Introduction: Understanding Fall Protection Height

In the world of workplace safety, fall protection height is a critical concept that employers must comprehend. Falls from heights are one of the leading causes of injuries and fatalities in many industries. Consequently, understanding how height influences fall protection requirements is essential for safeguarding workers. The Occupational Safety and Health Administration (OSHA) has established specific standards to enhance safety measures and mitigate fall risks based on the height of the work being performed. This article will delve into why fall protection height matters, outline OSHA regulations, and provide key insights for employers to maintain a safe work environment.

Significance of Fall Protection Height

- Definition of Fall Protection Height: Fall protection height refers to the specific elevations at which fall protection measures must be implemented. OSHA sets these heights to minimize the risks associated with working at elevated levels. The commonly referenced heights are generally 4 feet for general industry and 6 feet for construction, but specific scenarios may require fall protection at different elevations.

- Factors Affecting Fall Protection Usage: Height is not the only consideration; environmental conditions, the nature of work being performed, and equipment used can also significantly influence when and how fall protection measures should be employed. Therefore, recognizing the height at which employees may be at risk is paramount for establishing effective safety measures.

- Legal Obligations for Employers: Employers have a legal responsibility to protect their workers. Complying with OSHA standards concerning fall protection height ensures that organizations meet their legal obligations while prioritizing the health and safety of their employees.

By grasping the significance of fall protection height, employers can better prepare to mitigate risks associated with working at elevations.

OSHA Regulations on Fall Protection Height

- Overview of OSHA’s Implementation: The Occupational Safety and Health Administration (OSHA) has created regulations focused on fall protection to protect workers engaged in activities at heights. These regulations specify the required safety measures and when they should be implemented based on height.

- The 4-Foot and 6-Foot Rules: OSHA’s guidelines establish different thresholds for fall protection requirements:

- 4-Foot Rule: For general industry, fall protection is required when working at heights of 4 feet or more. This includes various activities, such as using ladders and working near edges where falls could occur.

- 6-Foot Rule: In the construction industry, fall protection measures must be used when employees are working at heights of 6 feet or more. This standard acknowledges the increased risks associated with construction activities.

- Specific Regulations: Detailed regulations under 29 CFR 1926.501 outline the requirements for fall protection in construction, emphasizing that fall protection systems need to be employed when workers are at risk during scaffolding, ladders, or roofing work.

- Importance of Compliance: Compliance with OSHA regulations is crucial for ensuring worker safety and avoiding costly fines. Organizations that adhere to these standards demonstrate a commitment to creating a safe work environment.

Understanding and adhering to OSHA regulations surrounding fall protection height plays a vital role in workplace safety.

Best Practices for Implementing Fall Protection Height Standards

- Conduct Comprehensive Risk Assessments: Employers should conduct thorough risk assessments to identify potential fall hazards within their work environment. These assessments help establish appropriate safety measures based on height and specific job tasks.

- Train Employees on Fall Protection: Providing ongoing training for employees is essential. Workers should be educated on the potential fall hazards linked with different heights, how to use fall protection systems, and the importance of adhering to safety protocols.

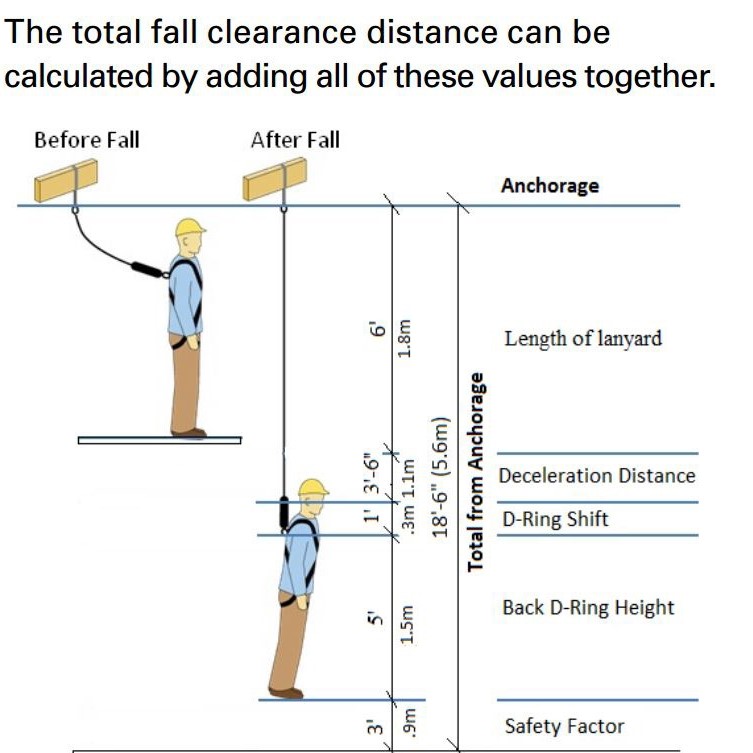

- Ensure Equipment Availability and Functionality: Employers must provide adequate fall protection equipment, including harnesses, lanyards, safety nets, and guardrails. Regular inspections and maintenance of this equipment are critical to ensure it operates effectively when needed.

- Develop Clear Safety Protocols: Organizations should establish comprehensive safety protocols that clearly define the use of fall protection systems based on height. This includes outlining procedures for using ladders, scaffolding, and other elevated surfaces.

- Monitor Height Compliance: Regularly review and monitor compliance with established fall protection height requirements. This practice ensures that safety measures are continually enforced and adapted as necessary.

Implementing these best practices will help employers maintain a safer work environment while ensuring compliance with fall protection height regulations.

Common Misconceptions About Fall Protection Height

Assuming Lower Heights Are Safe

- Misconception Overview: One prevalent misconception in workplace safety is the belief that fall protection measures are unnecessary for heights below established regulatory thresholds. This assumption can lead to a false sense of security.

- Real Risks: Falls from lower heights can still result in severe injuries, such as fractures, concussions, or other significant trauma. For example, a fall from a height of just a few feet can cause serious harm, especially on hard surfaces.

- Risk Assessment Importance: Employers يجب أن conduct thorough assessments of all potential fall risks, regardless of height. This includes evaluating each work environment for the specific tasks being performed and how these tasks may expose workers to fall hazards.

- Implementing Safety Measures: Even at lower heights, it is vital to implement appropriate fall protection measures. This can include utilizing guardrails, harnesses, and establishing protocols to minimize the risk of falls.

- Awareness and Culture: Fostering a safety culture that does not underestimate risks at lower heights can improve overall safety and help to prevent accidents. Employees should be made aware of the importance of safety irrespective of the height they are working at.

Believing Equipment Alone Is Sufficient

- Misconception of Equipment: Another common misconception is the belief that simply having fall protection equipment on-site guarantees worker safety. This misconception can lead to complacency among both employers and employees.

- Importance of Proper Use: While having the right equipment is indeed essential, it does not guarantee safety. Workers must know how to properly use equipment, such as harnesses and lanyards, to maximize their effectiveness in preventing falls.

- Training and Protocols: Proper training and adherence to established safety protocols are critical components of an effective fall protection strategy. Employers should ensure that all workers receive comprehensive training on the use of safety equipment.

- Regular Inspections and Maintenance: Equipment must also be regularly inspected and maintained to ensure functionality. Relying solely on equipment without proper maintenance can lead to failures when they are needed most.

- Holistic Safety Approach: A successful safety program combines equipment, training, and culture. Emphasizing that equipment is one part of a broader safety system encourages a more responsible approach to fall protection.

Underestimating Environmental Factors

- Impact of Conditions: Many people often overlook how environmental factors can significantly influence fall risk. Conditions such as rain, snow, ice, or wind can create hazards regardless of the height involved.

- Increased Likelihood of Falls: For instance, wet or icy surfaces can increase slip hazards, while strong winds can make it challenging for workers on ladders or scaffolding to maintain their balance. These environmental risks heighten the dangers associated with heights, even when they appear low.

- Regular Assessments of Conditions: Employers should assess environmental conditions continually. This means being proactive in recognizing changes and adapting safety measures accordingly.

- Implementing Control Measures: To combat environmental risks, companies should implement specific safety measures, such as using non-slip surfaces, avoiding work in adverse weather, and ensuring proper training regarding environmental hazards.

- Employee Awareness: Workers should be educated about potential risks related to environmental conditions. Raising awareness helps individuals remain vigilant and promotes safer practices when operating in fluctuating conditions.

Neglecting the Importance of Regular Training

- Misconception About Training: Some employers mistakenly believe that providing one-time training is sufficient to ensure safety. This belief can lead to gaps in knowledge and awareness over time.

- Need for Continuous Training: Continuous training ensures that workers remain updated on the latest safety protocols and industry best practices. Regular refreshers help reinforce the importance of remaining vigilant about fall hazards.

- Addressing Changes in Regulations: Safety regulations and industry standards can change frequently. Providing ongoing training helps keep employees informed about these changes, ensuring compliance and safety.

- Skill Reinforcement: Regular training sessions allow workers to practice their skills and stay familiar with safety equipment, making it more likely they will respond effectively in emergency situations or when hazards arise.

- Building a Safety Culture: Establishing a culture of continuous improvement in safety through regular training promotes accountability and enhances the overall safety of the workplace. Employees who participate in regular training are more likely to be engaged and proactive about safety.

By correcting these misconceptions, firms can foster better safety practices and improve compliance with regulations regarding fall protection height.

Frequently Asked Questions (FAQs)

What Is the OSHA 4 Foot Rule?

The OSHA 4-foot rule requires that fall protection measures be implemented in general industry workplaces when employees are exposed to fall hazards at heights of 4 feet or more. This regulation is critical for maintaining safety across various job tasks.

What Is the OSHA 6 Foot Rule?

The OSHA 6-foot rule specifies that fall protection must be provided in the construction industry when workers are at heights of 6 feet or above. This rule is designed to protect workers who may be at risk of falling while performing tasks at elevated levels.

Conclusion: The Importance of Understanding Fall Protection Height

Understanding fall protection height is critical for employers who want to maintain compliance with OSHA regulations and enhance workplace safety. By recognizing the height requirements and implementing effective fall protection measures, organizations can significantly reduce the risk of falls and injuries.

From conducting risk assessments and providing proper training to ensuring compliance with regulations, every step contributes to creating a secure work environment. It is the responsibility of every employer to prioritize safety and protect their workers by adhering to established standards and fostering a culture of safety awareness.

By actively engaging in fall protection height compliance, employers not only safeguard their employees but also demonstrate their commitment to workplace safety.