Understanding Conventional Fall Protection

In every workplace, especially those involving heights, maintaining safety is of utmost importance. One of the critical issues that arise is the question of “when must employers provide conventional fall protection?” Understanding this topic is essential for both employers and employees. Conventional fall protection refers to a variety of systems designed to prevent falls from elevated surfaces. These systems can include guardrails, safety nets, and personal fall arrest systems that comply with OSHA standards. To ensure a safe working environment, it is crucial to grasp when these protections must be implemented.

Many work-related injuries stem from falls, highlighting the need for comprehensive fall protection measures. Employers have an obligation to create a safe environment and mitigate risks associated with height. This article will explore the specific circumstances that mandate the provision of conventional fall protection systems by employers, helping to clarify the responsibilities involved.

When Must Fall Protection Be Provided?

When must employers provide conventional fall protection? According to OSHA guidelines, various conditions necessitate the implementation of conventional fall protection. For example, fall protection must be provided in situations where workers are exposed to fall risks of six feet or more in the construction industry or when working at heights of four feet above a general industry floor.

This requirement implies that, during tasks involving ladders, scaffolding, or elevated surfaces, employers must ensure fall protection systems are available. These systems not only safeguard employee welfare but also help reduce potential liability for the employer.

Situations Requiring Fall Protection

There are several specific situations where fall protection must be made available to workers:

Working on Elevated Surfaces

- Definition: Elevated surfaces refer to any work areas that are raised significantly above ground level. Such as roofs, scaffolds, or mezzanines.

- Requirement for Fall Protection: Employees engaged in work on these surfaces must be provided with appropriate fall protection systems to prevent falls.

- Types of Fall Protection Systems: This may include guardrails, safety harnesses. And nets to ensure that workers are safe while performing tasks at height.

- Employer Responsibilities: Employers are responsible for assessing risks associated with working on elevated surfaces and implementing adequate fall protection measures according to safety regulations.

Accessing Ladders or Stairways

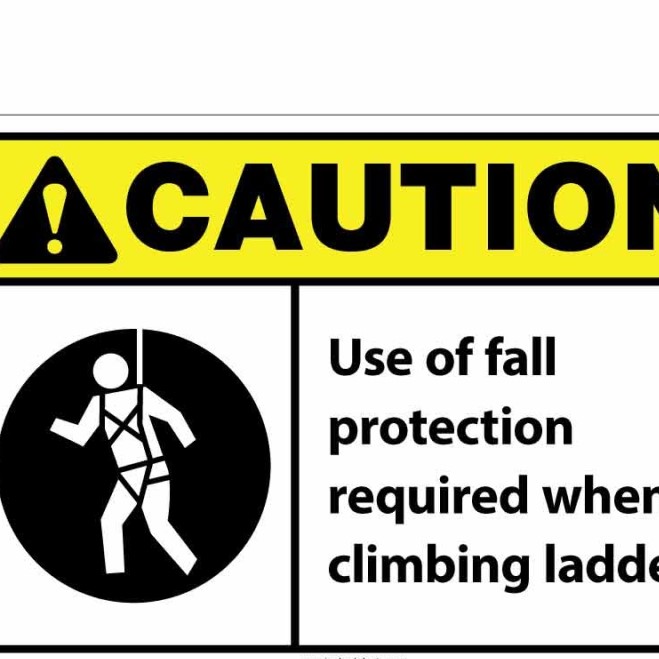

- Height Thresholds: Specific height thresholds, typically defined by OSHA standards, dictate when fall protection is necessary while using ladders or stairways.

- Risk of Falls: Climbing ladders or stairways involves significant risk. Particularly when exceeding established height limits.

- Fall Protection Measures: Adequate fall protection can include safety harnesses, guardrails, or ladder stabilizers to prevent slips and falls during ascent or descent.

- Training: Workers should be trained on the safe use of ladders and stairs. Including identifying risks and utilizing fall protection as needed.

Underlying Hazards

- Identifying Hazards: Even when a worker is at a height below established thresholds. The conditions beneath them can create potential hazards that necessitate fall protection.

- Examples of Hazards: These hazards may include sharp objects, machinery. or other dangers that could cause injury if a fall occurs.

- Proactive Measures: Assessing the area below the worksite for such hazards should be part of the safety evaluation process to determine the need for fall protection.

- Contextual Consideration: Employers should consider the unique circumstances of each job site to implement suitable safety measures, ensuring comprehensive protection.

Tasks Involving Aerial Lifts

- Definition of Aerial Lifts: Aerial lifts are equipment used to elevate workers to heights. Such as scissor lifts or boom lifts, requiring special safety considerations.

- Mandatory Fall Protection: The use of aerial lifts mandates the implementation of fall protection systems due to the inherent risks of working at elevation.

- Safety Features: Fall protection measures for aerial lift tasks can include harnesses. Guardrails on the lift platform, and proper training in using the equipment safely.

- Employer Obligations: Employers must provide the necessary equipment and training to ensure that workers can operate aerial lifts safely and effectively.

Overhead Work

- Definition of Overhead Work: Overhead work includes any tasks where employees are working above the heads of other workers or equipment.

- Risk of Falling Objects: There is a significant risk that tools or materials can fall, posing threats to individuals below.

- Fall Protection Requirements: To prevent injuries, workers engaged in overhead tasks must have fall protection systems in place, such as tool lanyards and nets.

- Communication and Safety Protocols: Employers should establish clear communication protocols to alert workers below when overhead work is taking place and implement safety measures to protect them from falling objects.

By understanding these specific situations, both employers and employees can ensure compliance with safety regulations and uphold worker welfare.

What Is an Employer’s Duty to Have Fall Protection?

It is essential for employers to recognize their duty in providing fall protection. The primary responsibility lies in assessing the workplace for fall hazards and determining appropriate measures to mitigate these risks. Employers must:

- Conduct Regular Assessments: Regular assessments should be carried out to identify potential fall hazards in the workplace and evaluate current safety systems.

- Implement Required Safety Measures: Once hazards are identified, employers are obligated to implement necessary fall protection systems. Ensuring they adhere to OSHA standards and regulations.

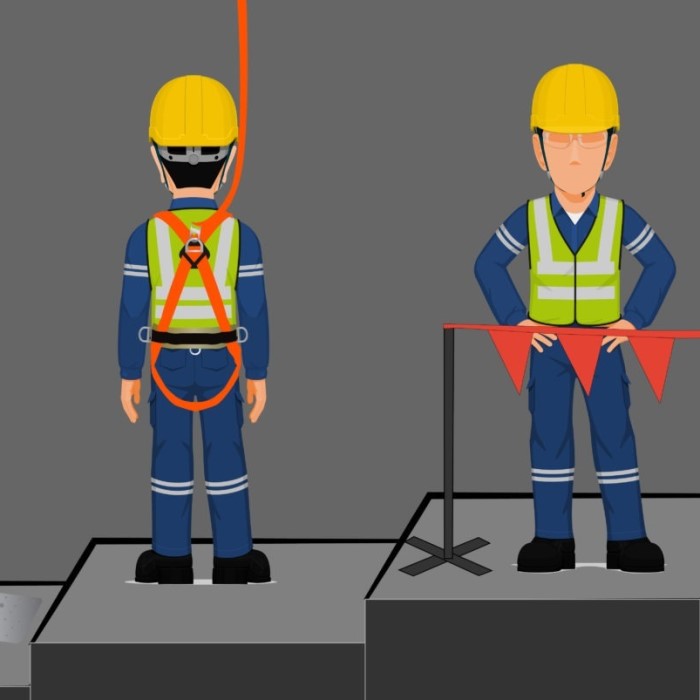

- Train Employees: Employers must provide training for employees on the correct usage of fall protection systems. Including how to properly wear harnesses, secure themselves, and use equipment safely.

- Maintain Equipment: All fall protection equipment should be regularly inspected and maintained to ensure it remains functional and effective.

Keeping the above responsibilities in mind is crucial for employers in mitigating risks associated with falls. By prioritizing employee safety, employers can help create a safer working environment, reducing incidents of injuries and accidents.

What is Conventional Fall Protection?

Conventional fall protection encompasses a wide range of safety measures designed to prevent falls in workplaces. It can include several types of systems, such as:

- Guardrails: These barriers prevent workers from falling off elevated surfaces.

- Safety Nets: Installed below working areas, these nets catch individuals in the event of a fall.

- Personal Fall Arrest Systems (PFAS): PFAS includes harnesses and lanyards that secure the worker and catch them if they fall.

Proper implementation of these systems is essential, given that each system can suit to various work environments and conditions. Understanding conventional fall protection allows employers to select the most appropriate solutions for their workforce.

The Importance of Fall Protection Training

Alongside the provision of conventional fall protection systems, employee training plays a critical role in workplace safety. Employers must ensure that workers understand how to use fall protection equipment correctly, including the following key components:

Understanding Equipment Use

- Importance of Proper Use: Understanding how to properly use fall protection equipment. Such as safety harnesses, lanyards, and anchor points, is essential for worker safety.

- Training Requirements: Workers should receive thorough training on how to correctly put on and adjust safety harnesses to ensure a secure fit, which is crucial for their effectiveness.

- Understanding Anchor Points: Workers should familiarize themselves with various types of anchor points. This includes knowing the strength requirements and how to assess whether an anchor point is suitable for their specific tasks.

- Hands-On Training: Implementing hands-on training sessions allows workers to practice using the equipment in a controlled environment, enhancing their confidence and competence.

Identifying Hazards

- Recognizing Potential Hazards: Employees must train to identify various fall hazards present in their work environments. Including unprotected edges, slippery surfaces, or uneven ground.

- Importance of Proactive Safety Measures: Emphasizing proactive safety measures encourages workers to take the initiative to report hazards and suggest safety improvements to their supervisors.

- Conducting Regular Inspections: Training should include guidance on performing regular inspections of work areas and equipment to identify risks before they lead to accidents.

- Encouraging a Safety Culture: Creating a work culture that prioritizes safety can foster open communication. Enabling workers to feel comfortable discussing hazards and seeking clarification when uncertain.

- Using Visual Aids: Providing visual aids or checklists can help reinforce safety training. Making it easier for employees to remember key hazard identification techniques.

Emergency Procedures

- Importance of Preparedness: Teaching employees emergency procedures is critical to ensuring they prepare to respond effectively in the event of a fall or other incidents.

- First Aid Training: Providing first aid training, including CPR and immobilization techniques, equips employees with the skills needed to assist fallen coworkers until medical professionals arrive.

- Conducting Drills: Regularly conducting emergency response drills can help reinforce training and familiarize employees with the procedures they must follow during an actual emergency.

- Communication During Emergencies: Training should emphasize the importance of clear communication during emergencies. Ensuring that employees know whom to contact and how to relay critical information quickly and accurately.

Training not only helps prevent accidents but also fosters a culture of safety within the workplace. By prioritizing education and awareness among employees, employers can significantly reduce the risk of falls and associated injuries.

Conclusion

In conclusion, understanding “when must employers provide conventional fall protection” is vital for ensuring a safe working environment. Employers have a duty to assess risks and implement necessary fall protection measures according to OSHA guidelines. By providing conventional fall protection systems and adequate training, employers can significantly reduce the risks associated with workplace falls.

As we continue to navigate the evolving landscape of workplace safety in 2025, staying informed about regulations and best practices is essential for protecting workers and ensuring a culture of safety. Ultimately, prioritizing fall protection will not only protect employees but also benefit employers by reducing liability and fostering a more efficient and productive work environment.