Introduction to Fall Protection in General Industry

Fall protection is crucial in preventing injuries in general industry workplaces. It ensures worker safety when tasks are performed at elevated heights. Every year, falls account for significant injuries and deaths in various industries. Thus, understanding fall protection is vital for creating safe work environments. General industry fall protection height requirements vary depending on the tasks and settings. According to regulations, protection is often necessary at heights of four feet or more. Recognizing these standards helps workplaces comply and protect their employees effectively.

Effective fall protection relies on evaluating risks and identifying hazards. This helps managers and workers select the right safety measures and equipment. Common hazards include unguarded edges, slippery surfaces, and unstable scaffolding. Addressing these risks minimizes accidents and improves overall safety.

Fall protection systems in general industry include guardrails, safety nets, and personal fall arrest systems. These systems must be appropriately installed and used. Additionally, maintaining equipment and ensuring proper training are vital for proper functionality.

Workplaces should prioritize safety by implementing well-planned fall protection strategies. This includes educating employees, following regulations, and regularly inspecting equipment. A proactive approach reduces risks and builds a culture of safety in general industry environments.

Regulatory Standards for Fall Protection

Regulatory standards for fall protection ensure workplace safety and compliance with laws. In general industry, these standards help prevent accidents and injuries due to falls.

OSHA Guidelines for Fall Protection

The Occupational Safety and Health Administration (OSHA) sets clear rules for fall protection. According to OSHA, fall protection is needed at heights of four feet or more in general industry. These rules apply to areas where workers face potential fall risks, such as ladders, elevated walkways, and platforms. Employers must provide safe working conditions and address hazards to meet OSHA standards.

Key Components of Compliance

Compliance with fall protection standards requires understanding specific requirements. Employers must:

- Identify fall hazards and risks in the workplace.

- Provide appropriate fall protection systems for employees.

- Train workers to use fall protection equipment correctly.

- Inspect and maintain fall protection equipment regularly.

- Follow all applicable OSHA regulations and standards.

Implementing safety measures as outlined above is crucial for preventing injuries.

Penalties for Non-Compliance

Failure to comply with fall protection standards can lead to serious consequences. OSHA may impose fines, penalties, or site closures for violations. These measures emphasize the importance of adhering to regulations and maintaining a safe work environment.

Benefits of Following Regulations

- Reduced risk of falls and injuries in the workplace.

- Improved worker confidence and productivity.

- Legal compliance and avoidance of penalties.

- Creation of a safer work environment for all employees.

Understanding and following regulatory standards help businesses protect workers and ensure safety in general industry.

Importance of Fall Protection in the Workplace

Fall protection saves lives and prevents injuries. It is essential for creating safe work environments. Falls are a leading cause of workplace accidents, especially in general industry. Proper fall protection ensures workers stay safe while performing tasks at heights.

Protecting Worker Health and Safety

- Fall protection reduces the risk of serious injuries and fatalities.

- It ensures workers feel secure while on the job.

- Safe environments improve physical and mental well-being.

Financial and Legal Benefits

- Fewer workplace accidents lower medical expenses and compensation claims.

- Complying with regulations avoids fines and legal problems.

- A safe workplace builds trust with employees and contractors.

Boosting Productivity and Morale

- Protected workers perform tasks more efficiently.

- Confidence in safety leads to higher morale and satisfaction.

- A focus on protection improves workplace standards and cooperation.

Investing in fall protection benefits both workers and employers. It creates a culture of safety and trust in the workplace.

Identifying Fall Hazards in General Industry Settings

Identifying fall hazards is vital for creating a safe workplace. In general industry settings, various risks can lead to falls. Recognizing these risks helps employers take preventative measures. Below are common fall hazards encountered and tips to mitigate them:

Common Fall Hazards in General Industry

- Unguarded Edges: Open edges on platforms or walkways can cause serious falls. Proper guardrails can reduce this risk.

- Slippery Surfaces: Wet or oily floors increase the chances of slips and falls. Routine cleaning and slip-resistant materials are essential.

- Unstable Scaffolding: Poorly constructed or unsteady scaffolds place workers at risk. Regular inspections ensure scaffolding remains secure.

- Improper Use of Ladders: Misusing ladders or using damaged ones can lead to falls. Workers should check ladders before use.

- Floor Openings: Holes in floors without proper coverings are major fall hazards. Cover and mark openings appropriately.

Steps to Identify and Address Fall Hazards

- Conduct a workplace hazard assessment regularly.

- Involve employees in safety audits to gather input.

- Review incident records to identify recurring risks.

- Use clear signage to warn workers of potential hazards.

Importance of Proactive Hazard Management

Addressing fall hazards proactively prevents accidents and injuries. It shows that employee safety is a top priority. Recognizing hazards early also ensures compliance with regulatory standards, including OSHA’s rules for general industry fall protection height requirements. A safe workplace fosters trust, morale, and productivity.

Types of Fall Protection Systems and Equipment

Fall protection systems and equipment are vital for ensuring worker safety at elevated heights. Understanding the different types available can help employers choose the most appropriate solutions. Below are the main types of fall protection systems and equipment used in general industry:

1. Guardrail Systems

Guardrail systems provide physical barriers around exposed edges. They prevent workers from accidentally falling off elevated surfaces. These systems are cost-effective and easy to install. They are ideal for areas like rooftops, walkways, and platforms.

2. Safety Net Systems

Safety nets catch workers if they fall. These systems are commonly used in construction and maintenance tasks. They should be installed near the work area for maximum effectiveness. Regular inspection is necessary to ensure their strength and durability.

3. Personal Fall Arrest Systems (PFAS)

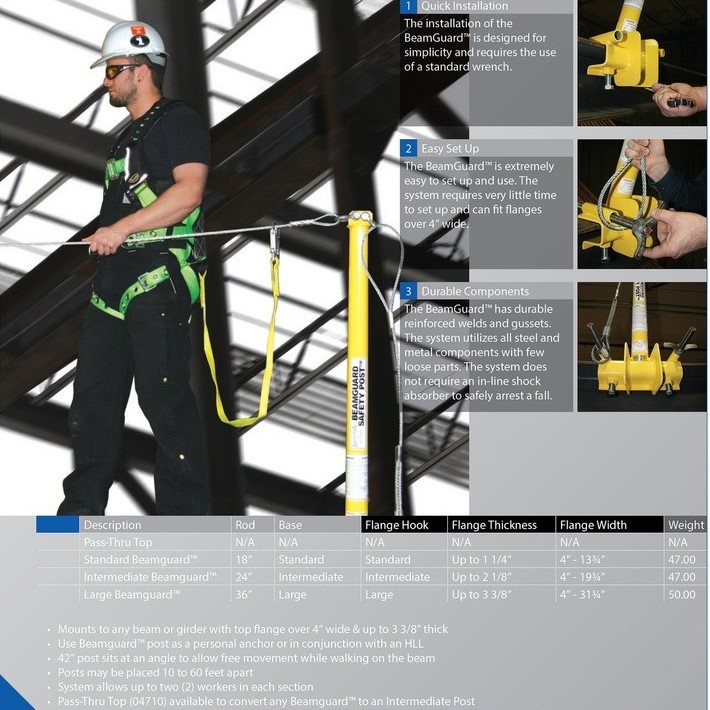

PFAS are wearable systems that stop falls after they occur. These include a harness, lanyard, and anchor point. Workers must be trained to use this equipment correctly. Proper installation of anchor points is essential for the system to function safely.

4. Positioning Devices

Positioning devices hold workers in place while they work at heights. They are often used for tasks requiring free hands, such as maintenance or painting. These devices reduce strain and increase productivity. Workers should not rely on these devices alone for fall protection.

5. Warning Line Systems

Warning lines offer a visual reminder to alert workers about fall hazards. These are used in areas like rooftops without guardrails. A warning line system should include proper spacing and visible markers.

6. Fall Restraint Systems

Fall restraint systems prevent workers from reaching edges where they might fall. These usually consist of a harness and a short lanyard. Restraint systems are straightforward and effective for many worksites.

7. Ladder Safety Systems

Ladder safety systems include railings, cages, and harnesses. These minimize risks when climbing or working on ladders. Proper ladder setup and training are required for safe usage.

Choosing the Right System

Employers should evaluate job site hazards to select the correct system. Combining multiple systems may offer the best protection. Regular inspection and maintenance of all equipment are crucial for safety.

Investing in proper fall protection systems ensures compliance with general industry fall protection height regulations. This reduces risks and protects the well-being of employees.

Best Practices for Implementing Fall Protection

Implementing effective fall protection measures is essential for ensuring workplace safety. By following best practices, organizations can reduce the risks of accidents and comply with general industry fall protection height standards. Below are key strategies for successful implementation:

Conduct a Comprehensive Risk Assessment

- Assess the workplace to identify potential fall hazards.

- Evaluate tasks performed at elevated heights.

- Prioritize areas with high risks, such as unguarded edges and slippery surfaces.

Develop a Fall Protection Plan

- Create a site-specific fall protection plan for your workplace.

- Include clear procedures for using safety equipment and addressing risks.

- Regularly update the plan based on new hazards or regulatory changes.

Use Proper Fall Protection Systems

- Install guardrails around elevated work areas to prevent falls.

- Provide safety nets near high-risk zones for added protection.

- Ensure workers have access to personal fall arrest systems (PFAS).

Implement Visual Cues and Warning Systems

- Use warning lines to alert workers of potential fall hazards.

- Place signs and labels near dangerous areas to increase awareness.

- Clearly mark floor openings and areas lacking guardrails.

Provide Adequate Training

- Train all employees in fall protection systems and practices.

- Include hands-on sessions for using equipment like harnesses and anchors.

- Review OSHA’s general industry fall protection height guidelines.

Regularly Inspect Equipment

- Check safety systems and equipment for damage or wear.

- Replace faulty or outdated equipment to ensure safety.

- Log inspections and maintain a schedule for checks.

Promote a Safety-First Culture

- Involve employees in safety discussions and audits.

- Encourage reporting and addressing potential hazards.

- Reward staff for following safety practices and procedures.

Partner with Experts

- Consult with safety professionals to optimize your fall protection strategies.

- Stay updated on regulatory changes by engaging with industry experts.

- Use expert guidance to train employees and choose the right equipment.

By following these best practices, workplaces can effectively implement fall protection measures. This helps reduce workplace accidents, promotes compliance, and builds a strong culture of safety.

Training and Education for Effective Fall Protection

Proper training and education are vital for successful fall protection in general industry. Workers must understand risks, equipment, and safety measures to prevent falls effectively.

Importance of Training

- Training ensures workers understand how to use fall protection equipment safely.

- It reduces accidents caused by improper equipment use or misunderstanding of safety procedures.

- Informed employees are more likely to follow safety guidelines and report hazards promptly.

Key Training Topics

- Identifying Fall Risks: Educate employees to recognize workplace hazards like unguarded edges or slippery floors.

- Using Equipment: Train workers to correctly wear harnesses, secure anchor points, and use ladders.

- Emergency Procedures: Teach employees how to respond during a fall or equipment failure.

- Maintenance Practices: Instruct teams to inspect and maintain fall protection equipment regularly.

Methods to Educate Employees

- Conduct hands-on training sessions for realistic practice with equipment.

- Use visual aids like demonstrations and videos to reinforce important concepts.

- Provide written guides and resources outlining general industry fall protection height requirements.

Regular Refresher Training

- Update training sessions annually or when new hazards arise.

- Reassess skills to ensure workers remember safety procedures.

- Adjust programs to include changes in regulatory requirements, such as OSHA guidelines.

Benefits of Well-Trained Workers

- Reduced workplace injuries and fatalities.

- Increased compliance with industry standards.

- Empowered workers who feel confident using safety equipment properly.

- Safer, more productive workplace environments.

Investing in comprehensive training and education supports a proactive safety culture. It ensures all employees are equipped to work safely at elevated heights.

Inspection and Maintenance of Fall Protection Equipment

Regular inspection and maintenance of fall protection equipment are critical for ensuring worker safety. Properly functioning equipment minimizes risks and complies with general industry fall protection height standards.

Importance of Regular Inspections

- Identifies wear, damage, or malfunction in safety gear.

- Ensures all equipment meets required safety standards.

- Prevents failures that can lead to serious injuries.

Inspection Guidelines

- Frequency: Inspect equipment before each use and conduct formal inspections monthly.

- What to Check:

- Check harnesses for fraying or broken stitching.

- Inspect lanyards for cuts or signs of weakening.

- Verify anchor points are stable and secure.

- Examine guardrails, nets, and ladders for cracks or misalignment.

- Documentation: Maintain records of inspections to track equipment condition and repairs.

Best Practices for Maintenance

- Store equipment in a clean, dry place to prevent corrosion or damage.

- Replace worn-out or visibly damaged gear immediately.

- Follow manufacturer guidelines for caring for fall protection systems.

- Regularly test and evaluate anchor points for continued strength.

- Calibrate and verify movable components, such as retractable lifelines.

Training for Inspectors

- Train designated personnel to perform thorough equipment inspections.

- Teach workers to report defective or damaged safety tools.

- Update training when inspection procedures or equipment change.

Benefits of Proper Maintenance

- Prolongs the lifespan of fall protection systems.

- Reduces workplace accidents and equipment failures.

- Ensures compliance with OSHA and other regulatory standards.

- Builds employee trust in the safety measures of the workplace.

By inspecting and maintaining fall protection equipment, companies can protect lives and avoid costly accidents. A proactive approach fosters a safer, more reliable work environment.

Conclusion: Ensuring Safety Through Fall Protection

Understanding general industry fall protection height requirements is fundamental for maintaining a safe work environment. By adhering to regulations, employing effective fall protection systems, and providing comprehensive training, employers can significantly reduce the risk of falls. Playing an active role in promoting safety cultivates a culture that values employee well-being.

As technology advances, so too do the solutions for fall protection. Employers must stay informed about innovative safety practices and equipment. Ultimately, maintaining a proactive approach to fall protection ensures that everyone goes home safely at the end of the day. Building a culture of safety is a shared responsibility, paving the way for a more secure and compliant workplace.