Understanding

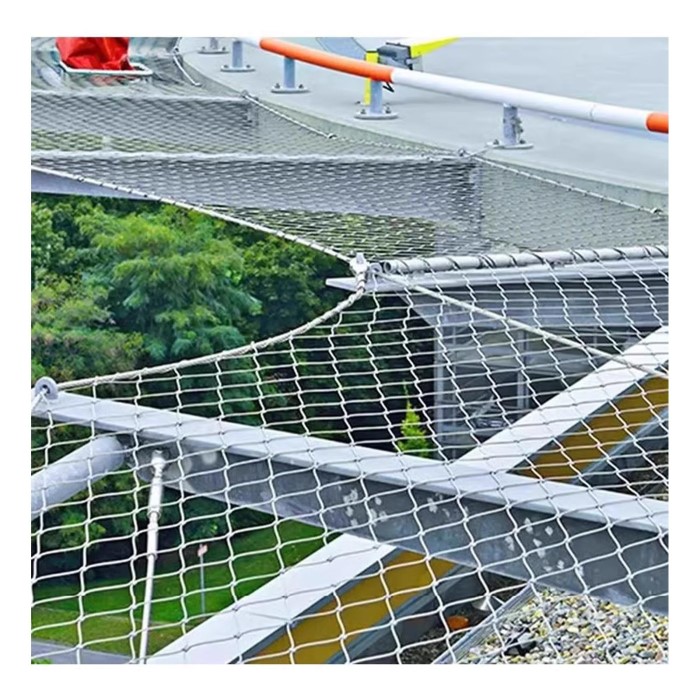

Fall protection netting is a vital safety feature in various industries, especially construction, aimed at preventing serious injuries or fatalities caused by falls from heights. This protective barrier is designed to catch workers if they accidentally fall, providing a critical safety cushion. In the construction sector, where workers are often elevated on scaffolds, rooftops, or other high platforms, the risks associated with falls are considerably elevated. Hence, implementing effective fall protection strategies is not just advisable but essential.

Constructed from high-strength synthetic materials, fall protection netting is engineered to absorb and dissipate impact forces, reducing the chance of injury. It acts as a safety measure designed not just to protect one individual but to cover a wide area where multiple workers may be at risk. Beyond its role in safeguarding human life, it also plays a significant part in compliance with legal standards and regulations, reinforcing an organization’s commitment to workplace safety.

Importance of Fall Protection Netting

The significance of fall protection netting cannot be overstated; it ultimately serves multiple purposes in the workplace. First and foremost, its primary goal is to protect workers from the dangers posed by falls. This form of netting is particularly crucial on construction sites, where a significant percentage of injuries arise from falls. According to the Occupational Safety and Health Administration (OSHA), falls account for a considerable number of accidents in the construction industry, highlighting the urgent need for effective safety measures.

Adopting fall protection netting not only enhances worker safety but also helps organizations reduce financial liabilities resulting from workplace injuries. Medical costs, legal fees, and lost productivity due to accidents can severely impact a company’s bottom line. Therefore, investing in the right safety equipment is both a moral obligation and a financially sound decision.

Benefits of Using Fall Protection Netting

- Injury Prevention: The most obvious benefit is the prevention of severe injuries or fatalities. Having a reliable safety net can make a substantial difference in the outcomes of accidental falls.

- Cost-Effectiveness: While the initial cost of installing fall protection netting may seem high, it can lead to significant savings in the long run. Organizations can avoid expensive medical bills and the long-term costs associated with worker compensation claims.

- Regulatory Compliance: Adhering to OSHA safety standards is critical for any construction business. Incorporating fall protection netting is one way to ensure compliance and avoid potential fines.

- Versatility: Fall protection netting isn’t limited to construction; it can be utilized in various settings, such as maintenance work, event staging, or anytime workers are at risk of falling from height.

Key Features of Quality

Selecting high-quality fall protection netting is essential for maximizing safety. Not all netting is created equal, and understanding what features to look for can make a significant difference:

High Tensile Strength

- Definition and Importance: High tensile strength refers to the material’s ability to resist breaking under tension. For safety netting, this characteristic is critical as it must endure the significant forces exerted during a fall without compromising its integrity.

- Material Selection: Choose netting materials made from high-quality fibers or composites, such as nylon or polyester, known for their durability. These materials should have been tested for tensile strength to ensure they can handle extreme conditions and impact forces.

- Compliance with Standards: It’s essential to ensure that the netting meets or exceeds established industry standards, such as those set by OSHA (Occupational Safety and Health Administration) or ANSI (American National Standards Institute). Compliance with these standards guarantees reliability and effectiveness in protecting personnel.

- Testing and Certification: Evaluate the netting through rigorous testing methods to verify its strength and performance. Look for certifications and quality assurance tests conducted by third-party organizations that confirm the product’s capabilities.

- Application Considerations: When selecting high tensile strength netting, consider the specific application and environment of use. Factors such as the height of falls, type of construction activity, and weight of tools or personnel will dictate the necessary strength requirements.

Weather Resistance

- Durability Against Elements: The netting material should be engineered to withstand various weather conditions that are common on construction sites. This includes resistance to rain, snow, wind, and temperature fluctuations.

- UV Protection: Since construction sites are often exposed to direct sunlight, it is crucial that the netting has UV resistance. UV protection prevents degradation, fading, and loss of tensile strength due to prolonged exposure to sunlight.

- Water Resistance: The netting should also be treated to resist water absorption and damage from moisture. This feature helps maintain the net’s effectiveness and extends its lifespan, preventing mold or mildew growth that could compromise its integrity.

- Impact of Weather on Safety: Consideration of weather resistance is not just about the netting’s durability; it’s also about safety. A weather-damaged netting system can fail to function correctly, posing a risk to the workers below. Ensuring weather resistance means that the netting will provide reliable support in varying conditions.

- Regular Inspections: Implement a routine inspection and maintenance schedule to assess the condition of the netting, especially after adverse weather events. This proactive approach will help identify any wear or damage that could affect safety.

Optimal Mesh Size

- Safety Functionality: The mesh size of the netting is critical in ensuring that it effectively catches falling personnel or tools while preventing small debris from passing through. An appropriate mesh size will help avoid potential injuries on the site.

- Airflow Considerations: It’s important that the mesh size is large enough to allow for sufficient airflow. Good airflow helps prevent the net from becoming a hazard in itself by minimizing wind resistance, which can potentially dislodge the netting during storms or high winds.

- Assessing Mesh Dimensions: A typical recommendation for mesh size is typically around 4 inches by 4 inches, although this may vary depending on specific job requirements and safety regulations. Assess the specific risks of the site to determine the best mesh dimensions for optimal safety.

- Balancing Strength and Size: While the mesh needs to be small enough to catch potential hazards, it must also retain high tensile strength. Make sure the selected material retains its durability even at the smaller mesh size to ensure ongoing protection against falls.

- Reviewing Regulations: Familiarize yourself with local safety regulations and guidelines that dictate appropriate mesh sizes for safety netting based on the type of work being performed. Compliance with these standards not only enhances safety but may also be required by law.

Maintenance and Regular Inspections

One of the often-overlooked aspects of fall protection netting is the need for regular maintenance and inspections. Safety netting should be subjected to routine checks to identify potential wear, tear, or any signs of deterioration. Inspections should include the following aspects:

- Checking for visible damage such as fraying or cuts in the netting.

- Inspecting anchor points to ensure they remain secure and stable.

- Reviewing installation to confirm that netting has not sagged or shifted from its original placement.

Employees should be trained to perform these inspections, recognizing that consistent maintenance is key to the netting’s effectiveness.

FAQs

What are the 5 C’s of safety netting?

The 5 C’s of safety netting are foundational concepts that enhance safety practices:

- Choice: Selecting the appropriate type of netting for specific job conditions.

- Condition: Ensuring that netting is in good working condition before each use.

- Configuration: Properly installing the netting to effectively cover all potential fall zones.

- Clearance: Maintaining adequate clearance below the netting to prevent injuries from impacts with the ground or other surfaces.

- Compromise: Regularly evaluating any changes in work environment that may affect the integrity of the netting.

What is the OSHA standard for safety nets?

OSHA’s standards for safety nets are defined in 29 CFR 1926.105. These regulations stipulate the requirements for the installation, maintenance, and upkeep of safety nets on job sites, ensuring that they effectively catch personnel during fall incidents.

What is the purpose of safety netting?

The primary purpose of safety netting is to act as a buffer zone that catches workers who may fall from elevated heights, thereby mitigating the risk of serious injury or death. It is a proactive measure designed to create a safer work environment.

How to secure safety netting?

Securing safety netting involves several critical steps:

- It should be anchored to solid, stable structures to withstand impacts during falls.

- Regular tensioning may be necessary to prevent sagging, ensuring the net remains effective.

- Consistent inspections should be conducted to verify that the netting stays secure and intact.

Conclusion: The Role of Fall Protection Netting in Workplace Safety

In conclusion, fall protection netting represents a fundamental aspect of workplace safety, especially in high-risk environments like construction. By effectively preventing dangerous falls, this netting not only protects workers but also fosters a culture of safety within organizations.

Investing in high-quality fall protection netting, adhering to OSHA standards, and conducting regular inspections contribute significantly to workplace safety. Employers have a responsibility to create safe environments for their workers; fall protection netting is a proven solution to fulfill this obligation.

Ultimately, understanding the nuances of fall protection systems empowers both employers and employees to approach safety consciously. By prioritizing the implementation and maintenance of fall protection netting, the construction industry can significantly reduce the occurrence of falls, thereby preserving life and promoting a safer work environment.