What is SRL Fall Protection?

In any industrial or construction environment, workplace safety is a top priority. One critical component of ensuring safety is effective fall protection. The term SRL fall protection refers to the use of Self-Retracting Lanyards (SRLs) that provide crucial security against falls from heights. As we advance into 2025, understanding SRL fall protection becomes even more vital. This comprehensive guide will explore the importance of SRLs, their function, and how they contribute to overall workplace safety.

Definition and Purpose of SRLs

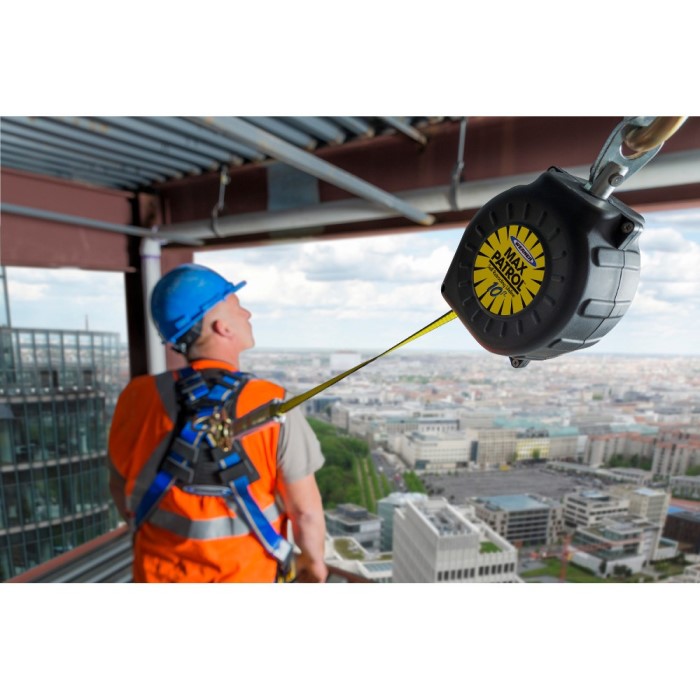

SRLs are personal protective equipment used in fall arrest systems. Their primary purpose is to stop a fall quickly. These devices consist of a retractable lifeline housed in a casing. Workers attach the lifeline to their safety harnesses. When a fall occurs, the SRL’s internal braking mechanism activates to limit the fall distance and minimize injury.

The retracting feature ensures the lifeline stays taut, reducing tripping hazards. SRLs are crucial for tasks like construction, maintenance, or any job requiring height safety. They combine safety, versatility, and ease of use, making them a preferred choice in fall protection systems.

Key Components of SRL Systems

- Casing: Protects the internal mechanisms and stores the lifeline. Made of durable materials.

- Lifeline: The retractable line, typically made of steel cable, webbing, or synthetic rope.

- Braking System: Stops a fall by engaging quickly when sudden acceleration occurs.

- Connector: Attaches the SRL to secure anchor points or safety harnesses.

- Swivels and Hooks: Ensures smooth operation and reduces line twisting.

Each part of an SRL system plays a vital role in ensuring fall protection. Regular inspection and maintenance ensure these components function effectively. Properly understanding these elements can enhance workplace safety in height-related tasks.

How SRLs Work in Fall Protection

Self-retracting lifelines (SRLs) play a crucial role in fall protection. They are designed to ensure safety while working at heights. Understanding their mechanism and benefits highlights why they are vital in hazardous environments.

Mechanism and Functionality

SRLs use a retractable lifeline housed in a protective casing. This lifeline automatically adjusts to the user’s movement. When a worker falls, the SRL’s braking system activates almost instantly. It halts the fall by locking the lifeline at high speed. This minimizes the impact on the worker, reducing injury risks.

The retracting feature keeps the lifeline taut during operation. This reduces slack and prevents tripping hazards. Swivels and hooks ensure smooth movement and prevent the lifeline from twisting. These features combine to provide both safety and convenience.

Benefits of Using Self-Retracting Lifelines

- Enhanced Safety: SRLs arrest falls quickly, reducing the risk of severe injuries. The brake system reacts within milliseconds.

- Increased Mobility: The retractable design allows freedom of movement during work. Workers can focus on tasks without frequent adjustments.

- Reduced Hazards: The taut lifeline prevents excess slack, avoiding tangling or tripping risks.

- Versatility: SRLs are suitable for various tasks, from construction to industrial maintenance.

- Durability: Built with tough materials, SRLs withstand challenging environments and prolonged use.

Workers relying on SRLs gain both protection and operational efficiency. These devices are a cornerstone of modern fall protection systems.

Types of Self-Retracting Lifelines (SRLs)

Self-retracting lifelines (SRLs) come in various types to suit different jobs and industries. Understanding the classifications and material variations will help you pick the right SRL for your needs.

Classification Based on Use

SRLs are classified based on how and where they’re used. Here are the primary categories:

- Personal SRLs: Designed for individual workers, these are compact and lightweight. They connect directly to the harness, offering ease of movement. Personal SRLs are ideal for maintenance, utility, and similar tasks.

- Leading Edge SRLs: Designed for use over sharp edges or corners, they come with reinforced lifelines. They are critical in construction and roofing to withstand edge impact during a fall.

- Rescue SRLs: Equipped with additional rescue mechanisms, these SRLs enable quick retrieval of a fallen worker. They are important in emergency situations and confined spaces.

- Heavy-Duty SRLs: For industrial tasks, these SRLs can handle greater weights and harsher environments. They are built to endure rugged conditions common in oil rigs or large construction sites.

Material Differences and Application Scenarios

The materials used in SRL lifelines and casings impact their applications. Common material types include:

- Steel Cable Lifelines: Durable and strong, these are suitable for heavy-duty tasks. They work well in rugged environments such as construction or mining.

- Webbing Lifelines: Made from synthetic materials like nylon, these are lightweight and flexible. They are perfect for indoor tasks, light maintenance, or jobs requiring greater portability.

- Synthetic Rope Lifelines: These offer a balance between strength and flexibility. Ideal for tasks where both indoor and outdoor use is common.

- Reinforced Edge Materials: Found in leading-edge SRLs, these can resist wear over sharp edges.

Each type is designed to meet specific safety challenges. Selecting the correct SRL ensures reliable fall protection for any job.

Standards and Regulations for SRL Fall Protection

Understanding safety standards is crucial when using SRL fall protection systems. Compliance ensures reliability and legal safety requirements. OSHA and ANSI set these key guidelines.

OSHA Guidelines

The Occupational Safety and Health Administration (OSHA) governs fall protection regulations in the U.S. Employers must follow these rules to ensure workplace safety:

- General Industry Standards (29 CFR 1910): OSHA mandates fall protection for heights of 4 feet or higher.

- Construction Standards (29 CFR 1926): Requires fall protection systems, including SRLs, at 6 feet or more for construction tasks.

- Inspection and Maintenance: Employers must ensure SRLs are inspected regularly by qualified personnel.

- Anchorage Requirements: Anchor points must hold at least 5,000 pounds per individual SRL connection.

- Training Requirements: Workers must receive training on proper SRL use, inspection, and risks.

OSHA guidelines make safety a priority for both employers and employees.

ANSI Standards

The American National Standards Institute (ANSI) provides industry standards for SRL design and performance. These are voluntary but widely adopted for enhanced safety:

- ANSI Z359.14: Covers performance and testing of SRLs, including for leading-edge scenarios. It ensures the durability and reliability of devices.

- Marking and Labeling: SRLs must meet specific labeling requirements for easy identification and specific use cases.

- Dynamic Testing: Systems undergo rigorous tests to simulate fall arrest scenarios.

- Clear Safety Ratings: ANSI standards require clear braking distances and weight capacity ratings.

- Training and Competency: Emphasizes educating users about ANSI-rated equipment.

Together, OSHA and ANSI standards ensure SRL fall protection provides the highest level of safety. Employers should prioritize compliance with both to maintain a secure workplace.

Common Applications of SRL Fall Protection Systems

Self-retracting lifelines (SRLs) are essential for safety across various industries. Their versatility suits different applications, ensuring worker safety in challenging environments.

Industrial Worksites

SRLs are widely used in industrial environments where workers face height-related risks. Manufacturing plants, warehouses, and oil refineries often require SRLs for tasks such as machinery maintenance, pipeline inspections, and elevated workstations.

- Machinery Maintenance: Workers maintain heavy machinery at heights using SRLs to prevent falls.

- Pipeline Inspections: SRLs enable safe inspection of pipelines and tanks in industrial facilities.

- Elevated Workstations: Tasks on high platforms or scaffolds necessitate SRL usage for fall protection.

Industrial sites often involve heavy equipment and harsh conditions. SRLs designed with durable materials, such as steel cable lifelines, are ideal. They ensure both protection and reliability in these demanding environments.

Construction and High-Risk Jobs

In construction and high-risk jobs, SRLs are vital for ensuring worker safety. They are commonly used in activities like roofing, scaffold erection, and steel framework assembly.

- Roofing: SRLs prevent falls when workers install, repair, or inspect roofs.

- Scaffold Erection: Workers building or working on scaffolds rely on SRLs for secure fall protection.

- Steel Framework Assembly: SRLs provide safety during installation of steel beams and structures.

Leading-edge SRLs are often preferred in construction due to their reinforced lifelines. These designs withstand sharp edges and high-impact falls, ensuring safety in challenging environments. High-risk jobs demand versatile SRLs that offer ease of movement and swift fall arrest capabilities.

Both industrial and construction applications highlight the importance of SRLs. Choosing the right type ensures reliable fall protection in any hazardous task.

How to Choose the Right SRL for Your Needs

Choosing the right self-retracting lifeline (SRL) is vital for workplace safety. Various factors and options deserve careful consideration to ensure optimal protection and efficiency.

Factors to Consider When Choosing an SRL

- Job Requirements: Match the SRL type to the tasks performed, such as maintenance, construction, or rescue.

- Work Environment: Consider environmental conditions like exposure to sharp edges, chemicals, or extreme temperatures.

- Lifeline Material: Select steel cables for durability or webbing for flexibility based on the task.

- SRL Classification: Choose personal, leading edge, rescue, or heavy-duty SRLs depending on work specifics.

- Weight Capacity: Ensure the SRL can support the worker and their equipment without compromising safety.

- Compliance: Confirm the SRL meets OSHA and ANSI standards for fall protection reliability.

- Ease of Maintenance: Opt for SRLs with straightforward inspection and maintenance requirements.

- Budget: Balance cost with the required safety features and longevity.

Popular SRL Brands and Models

Various manufacturers offer reliable SRLs tailored to different needs. Explore these top brands and models:

- DBI-SALA: Popular for rugged construction and advanced braking systems. Suitable for industrial use.

- Guardian Fall Protection: Known for affordable, high-quality SRLs for construction and maintenance tasks.

- Honeywell Miller: Offers versatile SRLs with features like edge protection and rescue mechanisms.

- FallTech: Provides durable SRLs with ergonomic designs for worker comfort and safety.

- MSA Safety: Renowned for leading-edge SRLs designed for high-risk environments and heavy-duty jobs.

Researching popular brands helps identify SRLs best suited to your needs. Pairing the right features and compliance ensures reliable fall protection.

Maintenance and Inspection of SRL Systems

Regular maintenance and proper inspection of self-retracting lifelines (SRLs) are essential for safety. These practices ensure that the SRLs perform effectively and extend their lifespan. Neglecting maintenance can lead to equipment failure and workplace hazards.

Guidelines for Regular Maintenance

- Follow the Manufacturer’s Manual: Always refer to the SRL’s user manual for precise maintenance instructions.

- Clean Regularly: Remove dirt, grease, or debris from the lifeline and casing after every use.

- Inspect Before Use: Check for damages to components like the casing, lifeline, and connectors daily.

- Use Approved Cleaning Agents: Avoid harsh chemicals; use products recommended by the manufacturer.

- Test Braking Functionality: Engage the braking mechanism to verify proper operation before every use.

- Lubricate Moving Parts: Periodically apply lubricants to ensure smooth operation of internal mechanisms.

- Store Properly: Keep SRLs in a dry, clean space to avoid corrosion or material degradation.

- Schedule Professional Servicing: Arrange periodic inspections by certified professionals as required by OSHA or ANSI guidelines.

Consistent maintenance ensures user safety and compliance with industry standards. Skipping these steps can compromise the system’s integrity.

Signs of Wear and When to Replace Equipment

- Frayed or Damaged Lifeline: Replace if you see cuts, burns, or broken fibers in the lifeline.

- Corroded Components: Substitute parts showing rust or corrosion to maintain strength and reliability.

- Faulty Braking Mechanism: If the SRL fails to lock during testing, remove it from service immediately.

- Cracked or Broken Casing: Check the housing for visible damage; broken cases jeopardize internal mechanisms.

- Distorted Connectors: Replace hooks or carabiners that appear bent or misaligned.

- Excessive Internal Noise: Unusual sounds from the device may indicate internal issues requiring replacement.

- Expired Service Life: SRLs have a maximum lifespan as stated in the manufacturer’s guidelines; retire them when expired.

Ignoring worn parts can lead to serious accidents. Prompt replacement of faulty equipment ensures continued protection. Regular inspections are key to identifying these problems early.

Regular maintenance and timely replacements are cornerstones of SRL fall protection systems. Workers and employers should prioritize these practices to uphold safety at all times.

Tips for Proper Use of SRL Fall Protection

Proper use of self-retracting lifelines (SRLs) ensures workplace safety and dependable fall protection. Following guidelines can maximize the effectiveness of SRLs and minimize risks.

Best Practices for Setup and Operation

- Inspect SRLs Before Use: Always check the device for damage, wear, or malfunction.

- Secure Anchor Points: Attach SRLs to strong anchor points with a minimum of 5,000-pound capacity.

- Proper Harness Connection: Ensure the SRL connects securely to the harness’s dorsal D-ring.

- Check Lifeline Movement: Confirm the lifeline retracts smoothly and locks when tested.

- Maintain a Clear Path: Keep the area free of obstructions to avoid lifeline tangling.

- Use the Right SRL for the Job: Match the device to the task and environmental conditions.

- Follow Manufacturer’s Instructions: Always use the SRL as outlined in the user manual.

- Test Braking Mechanism Regularly: Manually test the braking system to ensure it locks efficiently during sudden falls.

- Train Workers: Provide proper training on SRL setup, usage, and limitations.

Adopting these practices ensures reliable SRL performance and worker safety.

Common Mistakes to Avoid

- Ignoring Regular Inspections: Skipping pre-use checks can lead to unnoticed defects or failures.

- Improper Harness Attachment: Incorrect connections reduce functionality and increase fall hazards.

- Using Damaged SRLs: Operating with worn or faulty devices compromises safety.

- Insecure Anchor Points: Weak or unapproved anchor points can fail during a fall.

- Overloading the Lifeline: Exceeding weight limits strains the system, risking malfunction.

- Using the Wrong SRL Type: Mismatched devices may not perform as needed for specific tasks.

- Bypassing Training: Lack of SRL training increases misuse and accidents.

- Improper Maintenance: Not cleaning or storing SRLs correctly reduces their lifespan and reliability.

Avoiding these mistakes safeguards workers and ensures compliant usage of SRL fall protection systems.

Conclusion: Prioritizing Safety with SRL Fall Protection

In summary, SRL fall protection plays a crucial role in improving workplace safety, especially in environments with potential fall hazards. Understanding its operation, selecting the right equipment, and adhering to best practices can create a safer work environment. As we look toward 2025, it is vital for all employers to prioritize SRL fall protection and integrate it into their broader safety strategies.

As discussed, implement SRL fall protection systems not only to comply with safety regulations but to actively protect your workforce. Enhanced safety leads to improved productivity and morale, ultimately contributing to a more successful operation. Embrace the advancements in SRL technology and ensure that safety remains a top priority in every workplace.