What Are Fall Protection Anchor Points?

Definition and Purpose

Fall protection anchor points are secure connection points for safety harnesses or lifelines. Workers rely on them to stay safe at heights. These anchors prevent falls and minimize injuries. They are essential in industries like construction, roofing, and maintenance. Anchor points can be fixed to buildings, structures, or machinery. Their design ensures stability and security in hazardous environments.

Importance of Anchor Points in Fall Protection Systems

Anchor points are central to any fall protection system. They provide the foundation for attaching safety equipment. A reliable anchor point reduces the risk of serious accidents. Without them, a fall arrest system cannot function properly. Properly chosen anchor points ensure worker safety and improve compliance with safety regulations. Additionally, they enhance confidence in working at elevated positions.

Types

Fall protection anchor points come in different types to suit various work environments and safety needs. Understanding these types helps workers choose the right anchor points for effective fall protection.

Permanent Anchor Points

Permanent anchor points are fixed to structures for long-term use. They are commonly found in factories, warehouses, and buildings. These anchors are durable and designed to withstand harsh conditions over time. They are ideal for places requiring consistent safety measures.

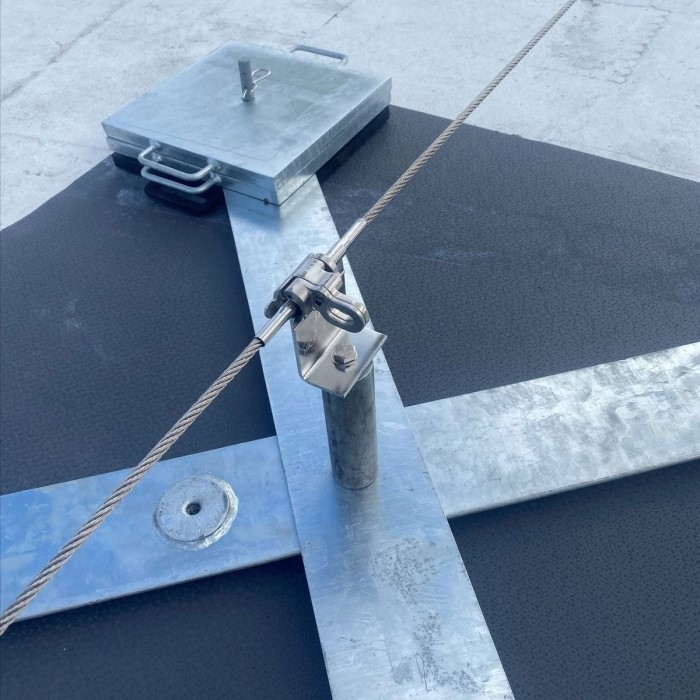

Temporary Anchor Points

Temporary anchor points are designed for short-term use. They are portable and easy to install and remove. Construction sites often use them for temporary tasks at heights. Workers can move these anchors as needed. They provide flexibility without compromising safety.

Structural Anchor Points

Structural anchor points are integrated into a building or structure. They are part of the design to ensure stability and safety. Common examples include beams, columns, or other structural elements used as anchor points. These anchors offer high load capacities and long-term reliability.

Materials Used in Anchor Points

Anchor points are made from various materials to suit different safety and durability needs. The choice of materials impacts their strength, longevity, and adaptability.

Steel and Alloy Composition

Steel and alloy are popular materials for anchor points due to their robustness. Alloys, like aluminum alloys, balance strength with lightweight design. These materials ensure durability, especially in harsh environments, such as construction sites or industrial settings. Steel and alloy anchor points are corrosion-resistant, providing consistent reliability over time.

Synthetic Material Options

Synthetic materials, such as high-strength textiles or polymers, are used for temporary anchor points. These materials combine flexibility with safety, allowing easy transport and installation. Synthetic anchor points are lightweight, which is ideal for workers frequently moving between locations. They also offer adaptability for different structures. However, their durability may be slightly lower than steel or alloy, making them better for short-term tasks in controlled environments.

Standards and Regulations for Anchor Points

Anchor points play a crucial role in ensuring safety during work at heights. They need to meet specific standards and regulations to be effective and compliant. Understanding these regulations helps ensure worker safety and avoids penalties.

OSHA Guidelines

The Occupational Safety and Health Administration (OSHA) provides strict regulations for fall protection anchor points. According to OSHA, anchor points must be capable of supporting at least 5,000 pounds per employee attached. This ensures they can handle the force exerted during a fall.

OSHA also requires that anchor points be placed at a height where they help reduce free fall distance. They should be inspected regularly to confirm their condition and strength. Proper installation and maintenance help ensure compliance with OSHA standards. Workers must be trained to use anchor points correctly to meet OSHA safety measures.

ANSI Standards

The American National Standards Institute (ANSI) develops additional safety standards for fall protection systems. ANSI Z359 is the specific set of guidelines that addresses fall protection anchor points. These standards focus on performance, testing, and design requirements for anchor points.

ANSI standards recommend using certified equipment and conducting detailed inspections. Anchor points must be tested to ensure they meet the required load capacity. The standards also emphasize compatibility with the overall fall protection system.

Compliance with ANSI standards improves safety and system reliability. Familiarity with these standards ensures effective use of anchor points while reducing fall hazards.

Installation of Anchor Points

Proper installation of anchor points is crucial for ensuring safety during work at heights. Mistakes during this process can compromise the effectiveness of fall protection systems.

Considerations for Accurate Installation

- Choose Appropriate Locations: Install anchor points at locations that minimize free fall distance. Ensure they are above the worker to reduce the risk of injury during a fall.

- Verify Structure Strength: Check the structure’s integrity where the anchor points will be placed. It must support the necessary load capacity.

- Use Certified Equipment: Select anchor points that meet OSHA and ANSI standards for fall protection. Certified products guarantee reliability and safety.

- Ensure Secure Attachment: Fasten the anchor points tightly to prevent slipping or detachment during use.

- Consult Installation Guidelines: Follow manufacturer instructions closely to ensure proper installation. Review technical specifications for accurate setup.

Common Mistakes During Installation

Incorrect Placement

- Understanding Fall Distance: When installing anchor points, it is crucial to avoid positioning them below a worker’s position. This is because if a fall occurs, the distance between the worker and the anchor point can significantly increase. A longer fall distance means a greater risk of injury upon landing.

- Optimal Placement: Ideally, anchor points should be installed at or above the level of the work area. This minimizes the potential fall distance and helps to ensure that workers are safer while performing their tasks.

Using Weak Structures

- Assessing Structural Integrity: It is vital to avoid attaching anchor points to structures that are weak, damaged, or not engineered to support the necessary loads.

- Consequences of Weak Structures: Using weak anchor points can lead to catastrophic failures during use. If the structure cannot hold the weight during a fall, it could collapse, putting the worker at risk of severe injury or even death.

- Choosing the Right Anchors: Always assess the structural integrity and load-bearing capacity of any surface before attaching an anchor. Consulting with a qualified engineer can help ensure safety compliance.

Ignoring Load Capacity

- Understanding Load Specifications: Each anchor point must be able to support a minimum load capacity, which is generally specified as 5,000 pounds for each attached worker.

- Consequences of Overloading: Ignoring the load capacity guidelines can result in anchor failure. If the combined weight of the worker and any equipment exceeds the anchor point’s load capacity, the anchor can fail, leading to dangerous falls.

- Safety Compliance: Always confirm that your anchor points are labeled properly and meet the required safety standards indicating they are suited for use.

Skipping Inspections

- Importance of Regular Checks: It is essential to conduct regular inspections on all installed anchor points. This should include looking for signs of wear, corrosion, or any other potential damage.

- Risks of Neglecting Maintenance: Skipping these inspections can result in unsafe conditions that may go unnoticed until a fall occurs. A regular inspection routine can help identify and rectify issues before they become critical failures.

- Documentation: Keeping a detailed log of inspections can help track the integrity of anchor points over time and ensure compliance with safety regulations.

Improper Fastening

- Securing Fasteners: Before each use, it is important to verify that all fasteners used in anchoring are secure and tightened properly according to manufacturer guidelines.

- Impact of Loose Fasteners: Loose or improperly secured attachments can increase the risk of accidents. A loose fastener might fail under load stress, leading to an uncontrolled fall for the worker.

- Routine Checks: Include fastening security as part of your pre-use inspection checklist. This ensures that all components are adequately secured and safe for operation.

Accurate installation ensures the effectiveness of anchor points in fall protection systems. Following safety considerations and avoiding mistakes improves worker safety and compliance with regulations.

Maintenance and Inspection of Anchor Points

Regular maintenance and inspection of fall protection anchor points are essential. These practices ensure their reliability and compliance with safety standards. Proper care minimizes risks and extends the lifespan of the anchor points.

Frequency of Inspections

- Daily Checks: Perform a quick visual inspection before every use. Look for obvious signs of damage or wear.

- Scheduled Inspections: Conduct thorough inspections at regular intervals. Ideally, do this every six months to one year.

- Post-Incident Inspections: Inspect anchor points immediately after any significant event, such as a fall or heavy load.

- Manufacturer Recommendations: Follow the inspection schedule suggested by the equipment manufacturer for specific guidelines.

Regular inspections reduce potential failures and ensure compliance with OSHA and ANSI standards.

Steps in Inspection Process

Examine Physical Condition

Begin by carefully checking the anchor point for any visible defects. Look for cracks, rust, or deformation that might compromise the integrity of the anchor. A thorough examination allows you to identify any potential weaknesses that could affect safety. When inspecting, pay attention to the overall condition and ensure that the surface is smooth and free from any irregularities. If you find any significant damage, take it as a serious concern that requires immediate attention.

Evaluate Attachment Points

Next, evaluate the attachment points to ensure they securely connect to the structure. Examine each connection for stability, looking for any signs of looseness or wear in the fasteners. A secure attachment is vital for the performance of the anchor point, so make sure that bolts, screws, or other fasteners are tight and properly seated. If you notice any worn components, schedule repairs or replacements as soon as possible to maintain safety.

Inspect Materials

When dealing with synthetic anchor points, perform a detailed inspection of the materials. Check for signs of fraying, tears, or UV damage, as these issues can significantly reduce the strength of the anchor. Inspect the entire length of the synthetic material, paying close attention to areas that experience high wear. If you detect any damage, consider replacing the affected parts to ensure reliable performance.

Test Load Capacity

Whenever feasible, test the anchor point’s ability to support the required load. Use appropriate testing methods to verify that the anchor can handle the forces it will encounter during use. This may involve applying a known weight or using specialized equipment designed for this purpose. Conducting load tests provides peace of mind, confirming the anchor point’s reliability under expected conditions.

Document Findings

As you complete the inspection, record your findings in a log. Note any issues you encounter, along with details about maintenance performed or needed repairs. Keeping a detailed log helps maintain a clear history of inspections and ensures accountability moving forward. This documentation serves as a valuable resource for future maintenance efforts and compliance.

Repair or Replace

When you identify any defects during the inspection, address them immediately. Repair any components that can be fixed safely but be prepared to replace items that show significant wear or cannot be adequately restored. Prioritizing repairs or replacements keeps the entire system functioning properly and ensures user safety.

Perform Functional Test

Finally, conduct a functional test to verify that the anchor point integrates properly with the fall protection system. Ensure that the anchor point fits securely and operates as intended during actual use. Performing this test confirms both the compatibility and functionality of the entire setup. If any discrepancies arise, make necessary adjustments or consult with a professional for further evaluation.

Following these steps ensures the anchor points remain fit for use. Scheduled and accurate inspections are key for worker safety.

Tips for Choosing the Right Anchor Points

Choosing the right fall protection anchor points is critical for safety and compliance. Proper selection ensures effectiveness and minimizes risks during work at heights. Here are two key factors to consider:

Evaluating Load Capacity

- Understand Weight Requirements: Determine the maximum weight the anchor point needs to support during use. OSHA recommends it should handle at least 5,000 pounds per attached worker.

- Account for Dynamic Force: Keep in mind the force exerted during a fall. Anchor points should withstand sudden impacts without failure.

- Review Load Ratings: Check manufacturer specifications for load capacity. Ensure it meets or exceeds the required standards.

- Inspect Lifeline Compatibility: Ensure the anchor point can support the combined weight of the user and attached lifeline equipment.

Proper evaluation of load capacity prevents overloading and enhances the safety of the entire system.

Compatibility with Your Fall Protection System

- Match Equipment Specifications: Ensure the anchor point works seamlessly with your safety harness or lifeline system. All components must function as an integrated unit.

- Assess Work Environment: Consider environmental factors like weather exposure, temperature changes, and structure type. Choose materials and designs that suit these conditions.

- Verify Connection Options: Check if the anchor point supports secure attachment for lifelines or harness connectors. Different systems may require specific types of connections.

- Consult Manufacturer Guidelines: Follow the instructions from both the anchor point and fall protection system manufacturers. Compatibility ensures reliability.

- Test Before Use: Perform a trial setup to confirm all equipment fits correctly and functions smoothly.

By evaluating load capacity and ensuring compatibility, you can select anchor points that maximize safety and system performance.

Conclusion: Ensuring Safe Work Environments

In conclusion, fall protection anchor points are indispensable in safeguarding workers from fall-related injuries. Understanding their types, adhering to safety standards, and utilizing personal fall arrest systems are all essential components in promoting a safe work environment.

It’s important for employers and workers alike to prioritize safety by regularly reviewing and updating their knowledge regarding anchor points and fall protection systems. By doing so, they contribute to a culture of safety that can ultimately save lives.