Understanding OSHA Electrical Panel Clearance Guidelines

Proper clearance around electrical panels is key to osha electrical panel safety requirements. OSHA guidelines focus on unblocked access to panels for safe operation and maintenance.

The Importance of Unobstructed Access and Egress Pathways

Free access to electrical panels is a must. This prevents safety risks during emergency shutdowns or regular maintenance.

Clear Working Area Specifications

OSHA mandates a minimum of 3 feet clear space in front of panels. This space should be kept free of any items.

Width and Height Requirements for Safety

The space in front of panels must be at least 30 inches wide. Panel height should allow easy access without using steps.

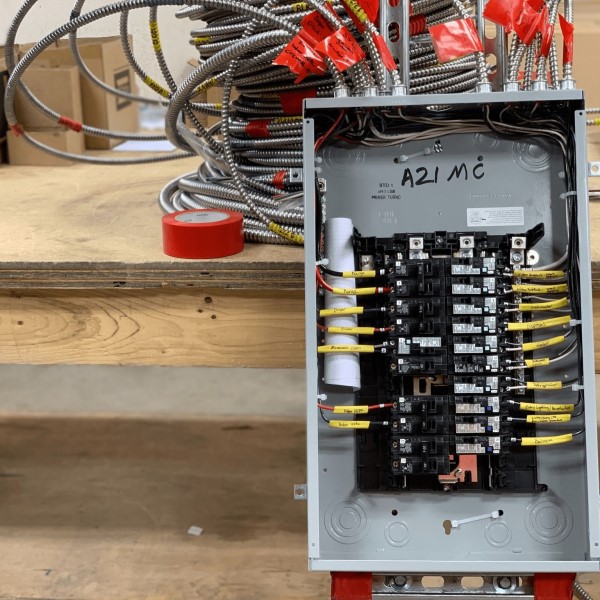

Proper Guarding and Clear Labeling Necessities

Panels must have barriers to prevent contact with live parts. Clear labels on panels aid in quick and safe operation.

Adequate Lighting and Visible Signage

Well-lit panel areas reduce the risk of accidents. Visible signage helps guide workers and supports safety protocols.

NEC Clearance Requirements for Electrical Panels

Proper spacing around electrical panels is vital for safety. The National Electrical Code (NEC) sets strict rules for panel clearance.

Depth and Width of Working Space Around Panels

Electrical panels require a clear space in front of them. This ensures safety during work. NEC mandates a minimum depth of 3 feet. Width must be at least 30 inches or the panel width, whichever is greater.

Dedicated Space and Mounting Height Considerations

Panels must have free space around them. This space must not have any pipes or ducts. Mounting height should allow easy access for operation and maintenance tasks.

Operating Height for Panel Controls

Panel controls must be within reach. The NEC recommends between 4 feet and 6 feet 7 inches from the floor. This helps prevent the need for risky reaching or climbing.

Clearances for Low and High Voltage Systems

Different voltages require different clearances. For low voltage systems, 3 feet is okay. High voltage systems may need more space to be safe.

Ensuring Ease of Access and Adequate Illumination

Panel areas must be accessible and well lit. This reduces risks during electrical work. Adequate lighting is necessary to see and perform tasks safely.

The Dangers of Inadequate Electrical Panel Clearance

Failing to meet OSHA electrical panel safety requirements leads to serious dangers.

Risks of Electrical Shock and Fires

Lack of clearance increases shock risks. Workers can touch live parts by accident. Close quarters also raise the risk of fires. Equipment may overheat, and sparks can ignite.

Impact on Electrical Equipment and Liability

Crowded panels lead to equipment damage. It’s harder to fix and maintain the panels. If someone gets hurt, building owners could face legal action. They could also pay large fines for safety violations.

Implementing Safety Best Practices

Safety in electrical panel maintenance is crucial. It starts with best practices every facility must follow.

The Role of Lockout Tagout Procedures

Lockout Tagout (LOTO) procedures protect workers during panel servicing. It ensures machines are off and can’t start unexpectedly. This is a must-do for any electrical work.

Regular Maintenance and Inspection Protocols

Frequent check-ups keep panels in top shape. Spotting issues early means workers stay safe. It also keeps equipment running smoothly.

Effective Use of Labeling and Signage

Clear labels and signs guide workers to safety. They show what each panel does, cutting down on mistakes. This makes emergency responses better and faster.

Avoiding Obstructions and Following Guidelines

Panels need clear space around them, as OSHA and NEC say. Keep the area unblocked. Follow set rules to stop accidents and issues before they start.

Complying with OSHA and NEC through Floor Marking and Space Management

Meeting OSHA and NEC standards for electrical panel clearances is crucial for safety. Floor marking and efficient space management aid in compliance and reduce risks.

Requirements for Clear Working Space

OSHA and NEC codes specify minimum distances around electrical panels. A clear working space ensures safety for routine operations and urgent situations. Mark these boundaries clearly for compliance.

Utilizing Floor Marking for Boundary Identification

Use floor marking tapes to outline clear working space. Choose colors and patterns that stand out and inform. This visual guide helps maintain necessary clearances around panels.

Tips for Ensuring Compliance in Different Environments

Every environment is unique—assess and adapt strategies for compliance. Maintain access to panels at all times, even in tight spaces. Regularly audit and adjust floor markings as needed.

Key Compliance Tips for OSHA Electrical Panel Safety Requirements

To ensure that your organization complies with OSHA electrical panel safety requirements, consider the following compliance tips:

Regular Inspections

- Frequency of Inspections: Schedule comprehensive inspections of electrical panels at predetermined intervals, such as monthly or quarterly. This consistency ensures timely detection of potential issues.

- Identification of Wear and Damage: During these inspections, look for signs of wear such as corrosion, fraying wires, or loose connections. Addressing these problems promptly can significantly minimize downtime and enhance safety.

- Risk Reduction: By identifying and rectifying issues early, the likelihood of accidents related to electrical panel failures is greatly diminished, thereby promoting a safer working environment.

Ensure Proper Grounding

- Importance of Grounding: Confirm that each electrical panel is effectively grounded to facilitate a safe electrical discharge, preventing dangerous static buildup.

- Protection Against Electrical Shocks: Proper grounding is essential to safeguard personnel from accidental electrical shocks, which can occur in the event of insulation failure or equipment malfunction.

- Fault Prevention: Grounding provides an effective defense against electrical faults, potentially averting hazardous situations such as short circuits or equipment fires.

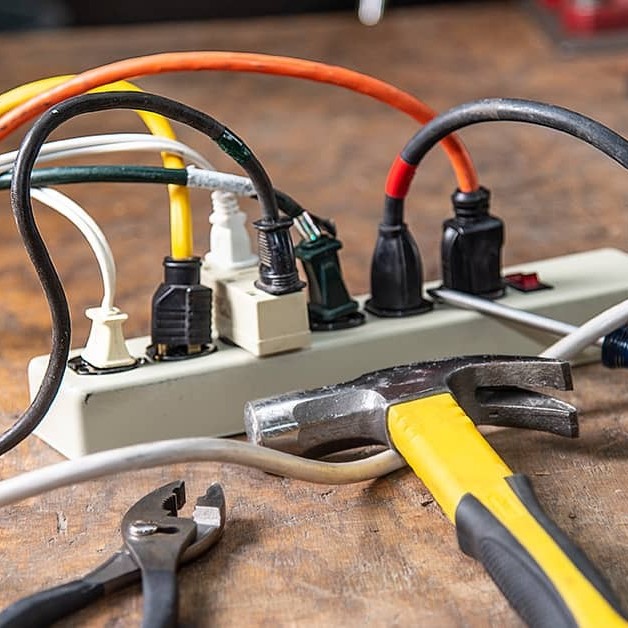

Keep Work Areas Clear

- Clutter-Free Environment: Regularly tidy the area surrounding electrical panels to ensure it remains free of tools, materials, or debris that could hinder access.

- Safe Access: An unobstructed workspace allows for easy and quick access during operation, maintenance, or in emergency situations, thereby enhancing overall safety.

- Minimize Hazards: A clean workspace helps to reduce the risk of trips, falls, or accidental contact with live electrical components, further promoting a safer work environment.

Utilize Lockout/Tagout Procedures

- Implementation of Procedures: Enforce lockout/tagout (LOTO) procedures to effectively control hazardous energy during maintenance or repair of electrical panels.

- De-energization Protocol: Before any maintenance work begins, ensure that electrical panels are completely de-energized, preventing any unexpected re-energization that could pose significant safety risks.

- Accidental Energization Prevention: Following proper LOTO practices is crucial for avoiding unintentional energization, providing peace of mind to workers when servicing electrical equipment.

Conduct Safety Training

- Regular Training Sessions: Schedule periodic training for all employees regarding the safe operation and handling of electrical panels to enhance their understanding of best practices.

- Hazard Awareness: Ensure that employees are knowledgeable about potential hazards associated with electrical panels and the importance of following established safety protocols.

- Emergency Response Training: Include practical instruction on how to react appropriately in case of emergencies, such as electric shocks or fire hazards, to equip employees with the necessary skills to respond effectively.

Document Compliance

- Record Keeping: Maintain detailed logs of all inspections, maintenance activities, and safety training sessions related to electrical panels to ensure accountability.

- Support for Compliance Efforts: Thorough documentation not only supports compliance with safety regulations but also serves as evidence during audits or inspections conducted by safety authorities.

- Continuous Improvement: Regularly review these records to identify trends, areas for improvement, and ensure ongoing adherence to safety standards.

Review Emergency Procedures

- Establishment of Procedures: Clearly define and communicate emergency procedures that address incidents involving electrical panels, including those for electric shocks and fire hazards.

- Regular Review and Updates: Periodically review and update these emergency procedures to reflect any changes in technology, equipment, or safety regulations.

- Employee Familiarization: Conduct drills and training sessions to ensure that employees are well-acquainted with emergency protocols, allowing for swift and effective responses during actual incidents.

Common Violations of OSHA Electrical Panel Safety Requirements

Being aware of common violations can help organizations proactively address potential issues. Here are some prevalent mistakes related to OSHA electrical panel safety requirements:

Inadequate Space

- Importance of Adequate Access: Maintaining the minimum required access space around electrical panels is essential for safe operation and efficient maintenance. This space allows personnel to work effectively, especially in emergencies.

- Common Violations: Many organizations overlook the importance of maintaining this access space, which is often cited as a common safety violation.

- Impact on Emergency Situations: Inadequate space can significantly hinder swift action during emergencies, making it difficult for workers to quickly shut down or access electrical systems when needed. This delay may exacerbate dangerous situations.

Lack of Labeling

- Need for Proper Labeling: Clear and accurate labeling of electrical panels and their associated circuits is crucial for safety and operational clarity.

- Risks of Confusion: Failing to label these components correctly can result in confusion among maintenance personnel, potentially leading to dangerous mistakes, such as working on the wrong circuit.

- Importance During Maintenance: Proper labeling ensures that employees can swiftly identify and isolate specific circuits during maintenance, reducing the risk of electrical shocks or inadvertent energization.

Poor Training

- Comprehensive Safety Training: It is vital that safety training related to electrical panel operations is thorough and covers all necessary aspects of safety protocols and procedures.

- Consequences of Insufficient Training: Employees who receive inadequate training may lack fundamental knowledge about the safe handling of electrical panels and the risks associated with improper use, increasing their chances of accidents.

- Ongoing Training Opportunities: Organizations should implement regular training refreshers and updates to adapt to new technologies and safety standards, ensuring all personnel are well-informed about best practices.

Neglecting Maintenance

- Critical Nature of Regular Maintenance: Routine maintenance of electrical panels is essential to identify potential issues before they escalate into hazards.

- Risks of Postponed Maintenance: Organizations that postpone or neglect necessary maintenance are more likely to experience electrical failures, which can lead to increased accident risks, costly repairs, and operational downtime.

- Establishing Maintenance Protocols: Creating and adhering to a structured maintenance schedule can significantly mitigate these risks, promoting a safer working environment.

No Lockout/Tagout Practices

- Importance of Lockout/Tagout (LOTO) Policies: Implementing effective lockout/tagout practices is vital for protecting employees during maintenance work on electrical panels.

- Risks of Not Implementing LOTO: Without these policies, there is a heightened risk of severe injuries due to unintended energization of electrical panels while personnel are conducting maintenance.

- Training on LOTO Procedures: Workers must be adequately trained on lockout/tagout procedures, ensuring they understand how to properly isolate power sources and secure panels to prevent accidental activation during servicing.

Best Practices for Electrical Panel Maintenance

Implementing best practices for electrical panel maintenance is crucial for compliance and safety. Consider these effective strategies:

Scheduled Maintenance

- Development of a Maintenance Schedule: Create a detailed maintenance schedule that specifies timeframes for regular inspections, cleaning, and necessary repairs for electrical panels.

- Adherence to Timelines: Stay organized by keeping track of the maintenance schedule and ensuring that all tasks are completed on time, reducing the risk of neglecting any crucial maintenance activities.

- Accountability and Documentation: Maintain records of completed maintenance tasks and any findings during inspections. This documentation helps identify trends and ensures accountability.

Thermal Imaging

- Utilization of Thermal Imaging Technology: Implement thermal imaging tools to assess electrical panels for abnormal heat patterns, which can indicate overheating or potential electrical faults.

- Early Detection of Issues: By identifying thermal anomalies early, maintenance teams can address problems before they escalate into significant issues, such as equipment failure or fire hazards.

- Routine Thermal Inspections: Schedule regular thermal imaging inspections as part of the maintenance routine to consistently monitor the condition of electrical panels.

Cleaning Procedures

- Regular Cleaning Intervals: Establish a routine for cleaning electrical panels at specified intervals to prevent dust and debris from accumulating.

- Impact of Dust on Performance: Educate staff on how dust buildup can lead to overheating of components, which increases the risk of electrical fires and reduces the overall efficiency of the panels.

- Proper Cleaning Techniques: Develop and enforce safe cleaning practices that avoid damaging components while effectively removing contaminants, ensuring the longevity and safety of the electrical panels.

Hardware Upgrades

- Assessment of Current Equipment: Regularly evaluate the condition and performance of components within electrical panels to determine if upgrades are necessary.

- Benefits of Upgrading Components: Recognize that outdated hardware may lead to operational inefficiencies, increased energy costs, and potential safety hazards, making timely upgrades essential.

- Implementation of New Technologies: Research and incorporate modern technologies and equipment that enhance performance, reliability, and safety standards within electrical panels.

Seek Professional Help

- Engagement of Licensed Electricians: Prioritize hiring qualified and licensed electricians for the evaluation, maintenance, and repair of electrical systems.

- Expertise in Safety Measures: Leverage the expertise of professionals to implement best practices in safety protocols, ensuring compliance with relevant regulations and enhancing workplace safety.

- Regular Assessments by Experts: Schedule periodic reviews and assessments by licensed electricians to identify and address any vulnerabilities in the electrical system, reinforcing overall safety and efficiency.

Conclusion: Ensuring Safety and Compliance with OSHA Regulations

In conclusion, understanding and adhering to OSHA electrical panel safety requirements is essential for any organization. These regulations play a vital role in ensuring the safety of employees and reducing operational risks. By implementing key compliance tips, maintaining accessible work areas, and providing thorough training, workplaces can foster a culture of safety.

Ultimately, recognizing the importance of compliance not only protects employees but also reinforces the organization’s commitment to maintaining a safe working environment. Regular audits and diligent safety practices safeguard against accidents and support OSHA compliance, ensuring long-term success in any business. By following the guidance outlined in this article, you can cultivate a safer workspace and promote best practices in electrical panel safety.