Understanding the Importance of Dust Masks in Woodworking

Woodworking is a highly rewarding activity, but it can also pose significant health risks if proper safety equipment is not utilized. Among the various forms of protective gear, a dust mask for woodworking stands out as a crucial piece of equipment for anyone involved in woodworking tasks. Not only does it help filter potentially harmful particles from the air, but it also significantly reduces the risk of respiratory problems. As wood particles become airborne during cutting, sanding, or grinding, they pose a direct threat to the lungs. Respiratory issues can manifest over time, and most woodworkers might not realize the cumulative damage until it is too late. Therefore, understanding the importance of using a dust mask is vital for every woodworking enthusiast or professional.

The Health Risks of Wood Dust

Wood dust is not merely an annoyance; it carries serious health implications. Studies have shown that inhaling wood dust can trigger a host of respiratory issues. Long-term exposure can lead to chronic conditions such as asthma, bronchitis, and even lung cancer. Furthermore, certain types of wood, like oak and cedar, can cause allergic reactions or other severe complications. As a woodworker, this is an issue you simply cannot ignore. Regular exposure to wood dust can result not just in immediate discomfort but also long-term health challenges. This means that wearing an appropriate dust mask is not optional; it is essential for your health.

Types of Dust Masks Used in Woodworking

When it comes to selecting a dust mask for woodworking, you essentially have two popular options: N95 masks and P100 masks.

- N95 Masks: These masks filter out approximately 95% of airborne particles, making them a solid choice for general woodworking. They are relatively inexpensive, and you can find them in most hardware stores. However, while they are effective against many types of dust, they may not provide complete protection against the smallest particles or certain harmful substances found in wood dust.

- P100 Masks: If you want a higher level of protection, look into P100 masks, which filter out 99.97% of airborne particles. This makes them an excellent option if you frequently work with fine dust or particularly hazardous materials. Though more expensive than N95 masks, they provide a greater level of safety, especially if you are working in an environment with high dust levels.

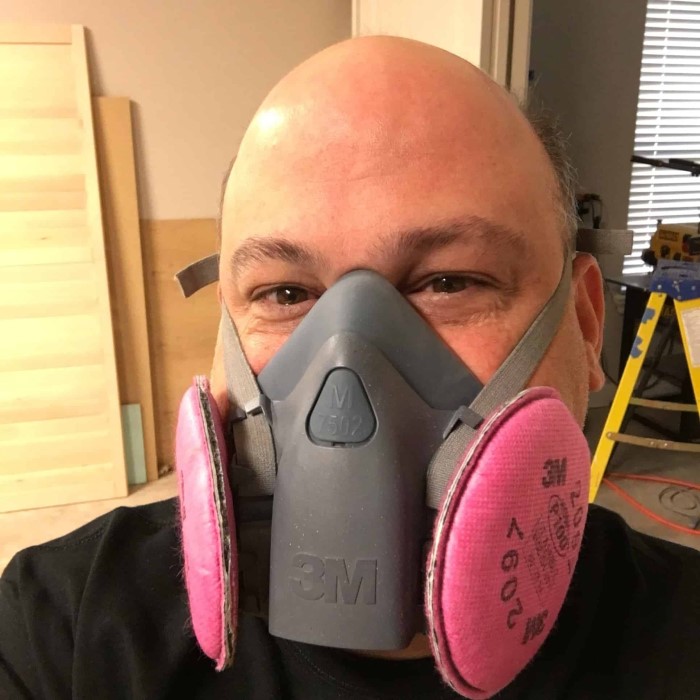

- Half-Face or Full-Face Respirators: These types of masks offer advanced protection and can be fitted with interchangeable filters tailored for specific particulate matter. They are particularly advantageous for those who perform more intensive woodworking tasks on a regular basis. Proper maintenance and correct fitting can make these masks comfortable enough for prolonged use.

How to Choose the Right Dust Mask for Your Needs

Choosing the right dust mask requires careful consideration of multiple factors:

- Filtration Efficiency: This is of paramount importance. Understand your working environment and the types of wood you will be using. If you’re commonly around sawdust or toxic materials, consider a P100 mask for enhanced protection.

- Fit Factor: A mask must fit snugly to protect effectively. Gaps can allow unfiltered air to enter. Make sure that the mask creates a tight seal around your nose and mouth, and consider masks with adjustable straps for a better fit.

- Comfort Level: The working conditions in woodworking can be quite variable. You may spend long hours wearing a mask, so it’s crucial to choose one that offers comfort. Look for padded straps and breathable materials to reduce discomfort during use.

- Utility for Specific Applications: If you plan to do a lot of fine cutting or sanding, the finer filtration offered by P100 masks may be beneficial. Otherwise, for general woodworking tasks, an N95 may suffice.

- Maintenance Requirements: Some masks are designed for single use while others are reusable. Reusable masks typically require regular filter changes and cleaning. Depending on your woodworking habits, assess which option is more practical for you.

Proper Usage of Dust Masks: A Safety Primer

Using a dust mask for woodworking correctly is essential for its effectiveness. Here are steps to ensure you are using a mask properly:

Clean Hands

- Importance of Hygiene: Before handling your dust mask, it is crucial to ensure that your hands are clean and free from any dirt, dust, or contaminants. This step is vital, as any particles on your hands can transfer directly to the mask.

- Washing Hands: Wash your hands thoroughly with soap and water for at least 20 seconds. If soap and water are not available, use a hand sanitizer with at least 60% alcohol. Clean hands will help you maintain a hygienic environment while using your mask.

- Avoiding Touching the Face: After washing your hands, avoid touching your face, particularly around your eyes, mouth, and nose, until the mask is in place. This further reduces the risk of contaminants entering your body.

Fit the Mask

- Correct Positioning: When you place the mask over your face, ensure that it covers both your mouth and nose completely. This positioning is essential for maximum filtration efficiency.

- Snug Fit: If your mask has adjustable straps, take the time to adjust them for a snug and secure fit. The mask should not be too tight to cause discomfort but should fit firmly enough to create an airtight seal against your skin.

- Check for Gaps: After fitting the mask, check for any gaps around the edges. Any openings can allow dust particles to bypass the mask’s filtration system, rendering it less effective. A properly fitted mask should feel secure and not shift easily when you move your head or talk.

Check for Integrity

- Visual Inspection: Before each use, conduct a thorough inspection of your mask for any signs of wear and tear. Look for holes, tears, or frayed edges that could compromise the mask’s ability to filter air effectively.

- Functionality of Straps: Also, inspect the straps to ensure they are intact and capable of holding the mask firmly in place. Damaged or broken straps will prevent the mask from fitting securely.

- Replacement Decision: If you find any defects during your inspection, do not use the mask. Always prioritize your health by replacing any compromised masks with a new one, as using a damaged mask can expose you to harmful particles.

Storage

- Post-Usage Care: After you have completed your woodworking task, it’s important to store your mask properly. Make sure it is placed in a clean, dry location to minimize the risk of contamination from other materials.

- Avoid Contamination: Avoid leaving the mask in places where it can come into contact with dirt, dust, or other contaminants. Ideally, use a dedicated storage bag to keep the mask clean when not in use.

- Proper Disposal of Disposable Masks: If you are using a disposable mask, remember to discard it after one use. Proper disposal means placing it in a sealed trash bag to prevent any potential contamination. This practice ensures that you are always using a fresh, uncontaminated mask each time you need to work with wood dust.

FAQ:

Which Mask is Better for Woodworking – P100 or N95?

When discussing masonry and woodworking, queries often arise about whether a P100 or an N95 mask is more suitable. The consensus is that P100 masks provide superior filtration. They filter out 99.97%, while N95 masks only filter 95%. If you often find yourself in high-dust environments, opting for a P100 mask is advisable.

Do I Need Anything Special for Wood Dust?

For wood dust, a standard N95 mask typically offers sufficient protection. However, if you are regularly cutting fine wood or using particularly aromatic or dusty woods like cedar or pine, a P100 mask might be more beneficial.

Which Mask Should I Wear While Cutting Wood?

When cutting wood, always opt for a mask that ensures a high level of filtration. A P100 mask is recommended, as it offers maximum protection against both larger wood particles and fine dust that can linger in the air and be easily inhaled.

What Additional PPE is Necessary?

In addition to wearing a suitable dust mask, consider using other PPE for complete protection during woodworking tasks. Safety goggles can safeguard your eyes from flying debris, gloves can help prevent splinters or cuts, and hearing protection is essential when operating loud machinery. Ensuring you have the right PPE creates a safer working environment.

Conclusion: Prioritizing Your Lungs with a Dust Mask

In the world of woodworking, the importance of using a suitable dust mask cannot be overstated. Dust masks play an integral role in safeguarding your lungs against harmful wood dust particles. By being educated about the types of masks available and understanding the proper usage guidelines, you can make informed decisions that prioritize your long-term health.

For any woodworking enthusiast, engaging with safety gear is not merely a suggestion; it’s a necessity. Make it a habit to wear your dust mask for woodworking every time you engage in woodworking activities. Remember, your lungs are irreplaceable, and taking preventive measures will ensure you can continue to enjoy this fulfilling craft for many years to come. Equip yourself with the best protection and savor the art of woodworking safely!