Introduction

Safety in the workplace, particularly in industries such as construction, climbing, and maintenance, cannot be overstated. The use of effective fall protection equipment is vital to safeguard workers. One essential piece of this equipment is the rope grab, designed to provide fall protection and allow workers to perform their duties safely. This article will delve into the features, benefits, and essential considerations surrounding rope grab fall protection, exploring why it is a necessary tool for ensuring workplace safety.

What is a Rope Grab System?

A rope grab system is an essential part of fall protection systems. It ensures workers’ safety when working at heights by providing controlled movement and automatic locking during falls. Rope grab systems are combined with lifelines and harnesses for effective fall arrest protection.

Definition and Functionality of Rope Grab Devices

Rope grab devices are mechanical components designed for fall protection. They attach to lifelines, allowing users to ascend or descend safely while working at height. These devices lock automatically when sudden force, such as a fall, is applied. This mechanism prevents workers from falling further and reduces the risk of injuries.

The main function is to allow smooth movement while ensuring immediate locking during a fall. Workers can easily adjust their position without compromising safety. Rope grab devices come in various designs to cater to different working conditions and safety needs.

Types of Rope Grab Systems (Manual vs. Automatic)

Rope grab systems are categorized into two types based on functionality:

- Manual Rope Grab Systems:

- Require manual adjustment by the worker.

- Offer complete control over positioning on the lifeline.

- Suitable for tasks requiring frequent repositioning.

- Automatic Rope Grab Systems:

- Adjust along the lifeline automatically.

- Lock instantly when a fall occurs.

- Ideal for tasks needing consistent protection during movement.

Both types of systems are designed to improve fall safety. Choosing between them depends on the specific work environment and user needs. Ensure compatibility with lifelines and proper training for optimal use.

Importance of Rope Grab Systems in Fall Protection

Rope grab systems are vital for worker safety in environments with elevated risks of falls. These systems work seamlessly with other fall protection tools to ensure safety.

Key Role in Personal Fall Arrest Systems

Rope grab systems are a crucial part of personal fall arrest systems (PFAS). They prevent life-threatening injuries during accidental falls by halting descent instantly.

The system provides dual advantages:

- Controlled Movement: Workers can ascend and descend safely without compromising balance.

- Instant Fall Arrest: The rope grab locks securely when sudden pressure is applied, stopping falls immediately.

These features allow workers to maintain mobility and focus on their tasks. Industries like construction and maintenance rely on them to meet safety standards and prevent workplace hazards.

Common Industries Utilizing Rope Grab Systems

Rope grab systems are used across various industries where workers face potential fall risks. Common sectors include:

- Construction: Workers on scaffolds, roofs, and high-rise structures depend on these systems.

- Telecommunications: Technicians climbing towers and poles need reliable fall protection.

- Energy Sector: These systems are essential for workers on wind turbines and oil rigs.

- Window Cleaning: Professionals working at heights benefit from controlled movements and safety.

These industries use rope grab systems to meet legal requirements, ensure worker safety, and reduce liability risks. Proper training and correct usage enhance their effectiveness in reducing accidents and fatalities.

Key Components of a Rope Grab System

Rope grab systems consist of several crucial components that work together for enhanced fall protection. Understanding these components is essential for correct usage and ensuring safety at height.

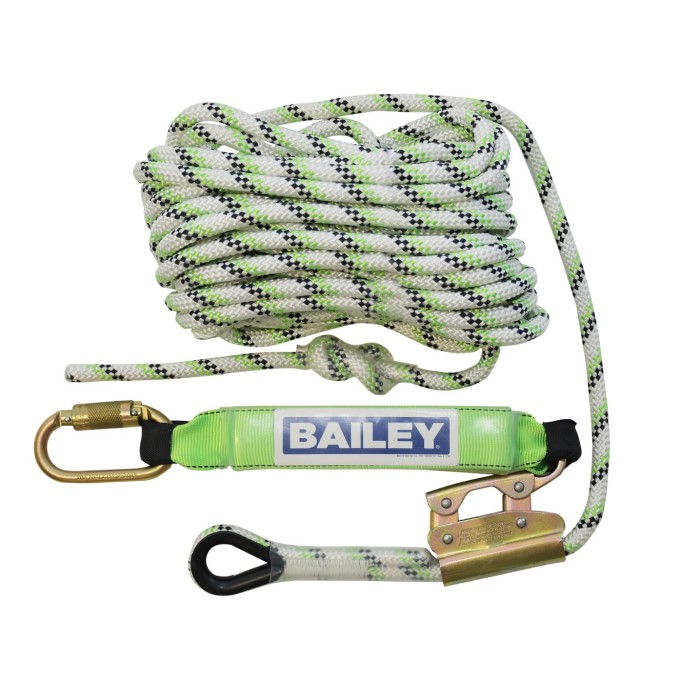

Rope Grab Device

The rope grab device is the heart of the system. It is a mechanical apparatus that attaches to the lifeline and ensures controlled movement along it. Its primary function is to provide mobility while automatically locking during sudden falls, preventing further descent and protecting workers from injury.

Rope grab devices come in various designs, such as manual and automatic systems, to suit different tasks and environments. Manual types require user adjustments for positioning, while automatic types adjust autonomously and lock during a fall. Proper selection of a rope grab fall protection based on the job and worker requirements is vital for safety.

Lifelines (Vertical and Horizontal)

Lifelines are rope or cable lines that serve as the pathway for the rope grab device. They are an integral component of the system, providing the surface on which the rope grab device operates.

- Vertical Lifelines: Used for ascending or descending, typically in environments like towers or construction sites.

- Horizontal Lifelines: Designed for horizontal movement, commonly used on scaffolds or rooftops.

Lifelines must be strong and properly anchored to prevent accidents. They should meet industry standards and be inspected regularly for wear and tear.

Harness and Connectors

Harnesses are worn by workers to distribute forces during a fall and minimize injury. They are directly connected to the rope grab system via connectors.

Key characteristics of a safe and reliable harness include:

- Comfortable fit during work activities.

- Strong, durable materials to withstand high forces.

- Adjustable straps for a secure and customizable fit.

Connectors, such as carabiners, attach the harness to the rope grab and lifeline. They enable a secure connection and must be well-maintained to function correctly.

Together, these components form a reliable system that ensures the safety of workers operating at height. Regular inspection and proper training are essential for maintaining the integrity of the rope grab system.

How Rope Grab Systems Work

Rope grab systems are vital equipment for fall protection while working at heights. They ensure worker safety through innovative mechanisms that enhance both mobility and immediate response during a fall.

Mechanism of Locking During a Fall

The locking mechanism in a rope grab system is its core functionality. Here’s how it works:

- Detection of Sudden Force: When a fall occurs, a sudden force is exerted on the lifeline.

- Automatic Locking: The rope grab device detects this force and locks instantly to halt the descent.

- Preventing Injuries: The secure locking minimizes fall distance, reducing injury risks for workers.

Automatic rope grabs use built-in sensors or cams that react immediately to jerking forces. This swift reaction ensures safety by stopping workers before they hit lower levels or the ground. Manual systems also have locking features but require user control for proper positioning.

Ensuring Smooth Movement Along the Lifeline

While preventing falls is crucial, rope grab systems also allow smooth worker movements along lifelines. Key elements enabling smooth movement include:

- Controlled Mobility: Workers can ascend or descend safely without losing balance or stability.

- Adjustable Rope Grab Devices: Manual and automatic grabs enable flexibility and adjustable positioning while working.

- Lifeline Compatibility: Vertical and horizontal lifelines provide pathways that facilitate almost unrestricted movement.

This balance between safety and mobility ensures that workers can perform their tasks efficiently. Whether it’s climbing towers or navigating rooftops, the rope grab system provides both protection and freedom. Regular training and maintenance enhance its functionality, ensuring it operates effectively across various environments.

Benefits of Using Rope Grab Systems

Rope grab systems are essential tools for fall safety. They offer multiple advantages to workers and industries.

Enhanced Safety for Workers at Heights

Rope grab systems significantly reduce fall-related risks. They prevent injuries by halting falls instantly. Workers gain confidence knowing their safety is secured. These systems keep workers stable while climbing or descending. Whether on rooftops or towers, they ensure safety in high-risk areas. Industries like construction and energy rely on them to maintain safe work environments.

Versatility in Various Environments

Rope grab systems adapt well to different job sites. They are effective in vertical and horizontal applications. Workers can use them on ladders, scaffolds, and towers. The systems are compatible with lifelines in various conditions. Their design ensures flexibility, making them suitable for many tasks. Industries like telecommunications and window cleaning use them for diverse fall protection needs.

Durable and Easy to Use

These systems are built with high-strength materials. Their durability ensures long-term reliable performance. Workers find them simple to operate with minimal adjustments needed. Automatic rope grabs provide ease with their self-adjusting feature. Proper training further enhances ease of use. Regular maintenance ensures they remain functional and safe for extended use.

Rope grab systems combine safety, versatility, and durability. They are vital for safeguarding workers across industries.

Considerations for Choosing the Right Rope Grab System

Choosing the right rope grab system is crucial for ensuring safety and optimal performance in fall protection. Proper selection of the system can prevent accidents and improve worker efficiency. Below are vital considerations to help you make an informed decision when selecting a rope grab system for your needs.

Compatibility with Lifelines

Ensure the rope grab system is compatible with the lifelines used at your worksite. Lifelines can be vertical or horizontal depending on the job requirements. Rope grab systems must function effectively on these lifelines for smooth operation. Check the material and diameter specifications of the lifeline to avoid mismatches. Compatibility ensures seamless movement and optimal locking performance during falls. Always confirm with the manufacturer for recommended pairings.

Load Capacity and Safety Standards

Evaluate the load capacity of the rope grab system to meet specific worker safety needs. Each system has an assigned weight limit that dictates its performance. Choose a system designed for the combined weight of the worker and their gear. Ensure it adheres to recognized safety standards, such as OSHA and ANSI regulations. Compliance guarantees the quality and reliability of the product. Check documentation to confirm certification by approved testing agencies.

Inspection and Maintenance Requirements

Regular inspection and maintenance are vital for the longevity of a rope grab system. Look for systems that require minimal maintenance but allow for thorough inspections. Check for wear and tear on the rope grab device and lifelines before each use. Replace any damaged components immediately to prevent accidents. Maintenance routines should be simple and outlined in the manufacturer’s guide. Scheduled inspections enhance safety and system reliability.

Selecting the right rope grab system is essential for worksite safety. Compatibility with lifelines, load capacity, and adherence to safety regulations are pivotal factors. Regular inspection and maintenance ensure the equipment remains reliable and functional over time. By making informed decisions, you boost safety and performance for workers at heights.

Proper Usage and Best Practices for Rope Grab Fall Protection

Proper use of rope grab systems is essential to maximize safety and effectiveness in fall protection. Workers and employers must follow certain guidelines to ensure optimal performance during tasks at height.

Training and Certification for Workers

Workers must undergo training before using rope grab devices. Training should cover:

- System Components: Understanding the rope grab device, lifeline, and harness setup.

- Proper Operation: Learning how to attach, adjust, and use the system effectively.

- Emergency Procedures: Knowing how to react if the system activates during a fall.

Certification ensures workers are competent in handling rope grab systems. Employers should provide periodic training updates to maintain worker skills.

Regular Inspection and Maintenance

Frequent inspections of rope grab systems are necessary to detect wear or damage. Best practices include:

- Pre-Use Checks: Inspect the rope grab, lifeline, and connectors daily for signs of damage or corrosion.

- Scheduled Maintenance: Follow manufacturer guidelines for cleaning and lubricating components to extend lifespan.

- Immediate Replacements: Replace damaged parts like torn lifelines or faulty rope grab devices immediately.

Regular inspection reduces the risk of system failure and ensures consistent safety performance.

Correct Positioning of the Rope Grab on the Lifeline

Always position the rope grab device properly for maximum safety. Key considerations include:

- Correct Orientation: Ensure the device is facing the proper direction indicated by the manufacturer.

- Secure Connection: Attach the rope grab firmly to the lifeline and harness without slack.

- Adjustable Placement: Position the device for easy movement but ensure it remains above the worker.

Proper positioning allows smooth mobility and immediate locking during a fall. Avoid tampering with settings to maintain mechanical integrity.

By following these best practices, workers can use rope grab systems safely and effectively to prevent falls and injuries.

Regulatory Standards and Compliance for Rope Grab Systems

Ensuring compliance with regulatory standards is crucial in implementing effective rope grab systems for fall protection. It guarantees safety and minimizes risks for workers while ensuring legal obligations are met.

OSHA Guidelines for Rope Grab Devices

The Occupational Safety and Health Administration (OSHA) has stringent guidelines for fall protection systems.

- Performance Requirements: Rope grab devices must meet specific performance criteria under OSHA guidelines. This includes proper locking during a fall and compatibility with lifelines.

- System Testing: OSHA mandates rigorous testing to ensure rope grab devices can withstand expected forces during falls. Follow approved testing methods to verify reliability.

- Training Requirements: Employers must provide thorough training for workers using rope grab systems. Training ensures workers understand proper usage and emergency procedures.

- Worksite Protection Plans: Organizations must implement a comprehensive fall protection plan that incorporates rope grab systems. This plan should identify hazards and detail preventive measures.

Compliance with OSHA guidelines ensures worker safety and avoids penalties or legal issues.

ANSI Standards for Fall Protection Equipment

The American National Standards Institute (ANSI) provides detailed standards for fall protection equipment, including rope grab systems.

- Equipment Design and Strength: ANSI standards specify material strength and design requirements for rope grab devices. Manufacturers must ensure systems meet these specifications.

- Load Capacity Testing: Devices must undergo load capacity tests to handle the combined weight of workers and equipment. Choose systems certified under ANSI standards to guarantee safety.

- Inspection and Maintenance Protocols: ANSI outlines maintenance protocols to keep rope grab systems functional. Regular inspections and prompt replacements for worn parts are essential.

- Fall Protection Suitability: ANSI recommends verifying equipment compatibility for specific industrial applications. Ensure device suitability for conditions like vertical or horizontal lifelines.

Adherence to ANSI ensures high-quality rope grab systems that perform well under various conditions.

Regulatory compliance with OSHA and ANSI is vital for effective rope grab system usage. Meeting these standards improves worker safety, reduces accidents, and ensures legal conformity.

Conclusion

In conclusion, rope grab fall protection gear is an indispensable tool for ensuring worker safety at heights. Its unique design features and functionality make it a popular choice among fall protection systems. As discussed, understanding the benefits, proper usage, and maintenance can significantly enhance safety efforts in various industries.

Investing in quality rope grab devices not only promotes a culture of safety but also aligns businesses with compliance regulations. Consequently, as workplace safety continues to gain importance, incorporating rope grabs into fall protection plans should be a priority. Ultimately, the goal is to protect workers, prevent injuries, and create a safer working environment for all. Remember, using proper rope grab fall protection is a key step towards achieving these objectives.